QTL TAPER BUSHINGS

INSTALLATION

12

Reversibility

QTL Bushings can be divided into two series

according to reversibility.

Reversible mounting series: type JA-J

have

three screws and three bores on the flange.

Un-reversible mounting series: type M-W

have

four tapped holes on the flange and no un-tapped

holes.

QTL TAPER BUSHINGS

Sizes JA - S

Selection

Peak torque ratings must not exceed torque ratings shown in the chart above. Capacity values shown

are for S.F. 1 Light loading start, work even.

For more severe duty divide torque capacity by the service factor (K) shown in the chart.

Working torque on shaft: T=63025N/n (lbf.in) N-

transmission torque (house);

n-shaft revolutions per minute(RPM)

Calculation torque TO=KT,K-loading coefficient.

When selecting bushing type, it should comply with TH <

TO. Bushing torque capacity can be determined from the

given table.

lbf . in

N.m

lbf . in

N.m

JA

1,000

113

54

6.1

SH

3,500

396

108

12.2

SK

7,000

791

180

20.3

SF

11,000

1,243

360

40.8

E

20,000

2,260

720

81.4

F

30,000

3,390

900

102

J

45,000

5,090

1,620

183

M

85,000

9,600

2,700

305

N

150,000

17,000

3,600

408

P

250,000

28,300

5,400

610

W

375,000

42,400

7,200

814

S

625,000

70,600

9,000

1,020

Part No

Torque Capacity

Screw Tightening Torque

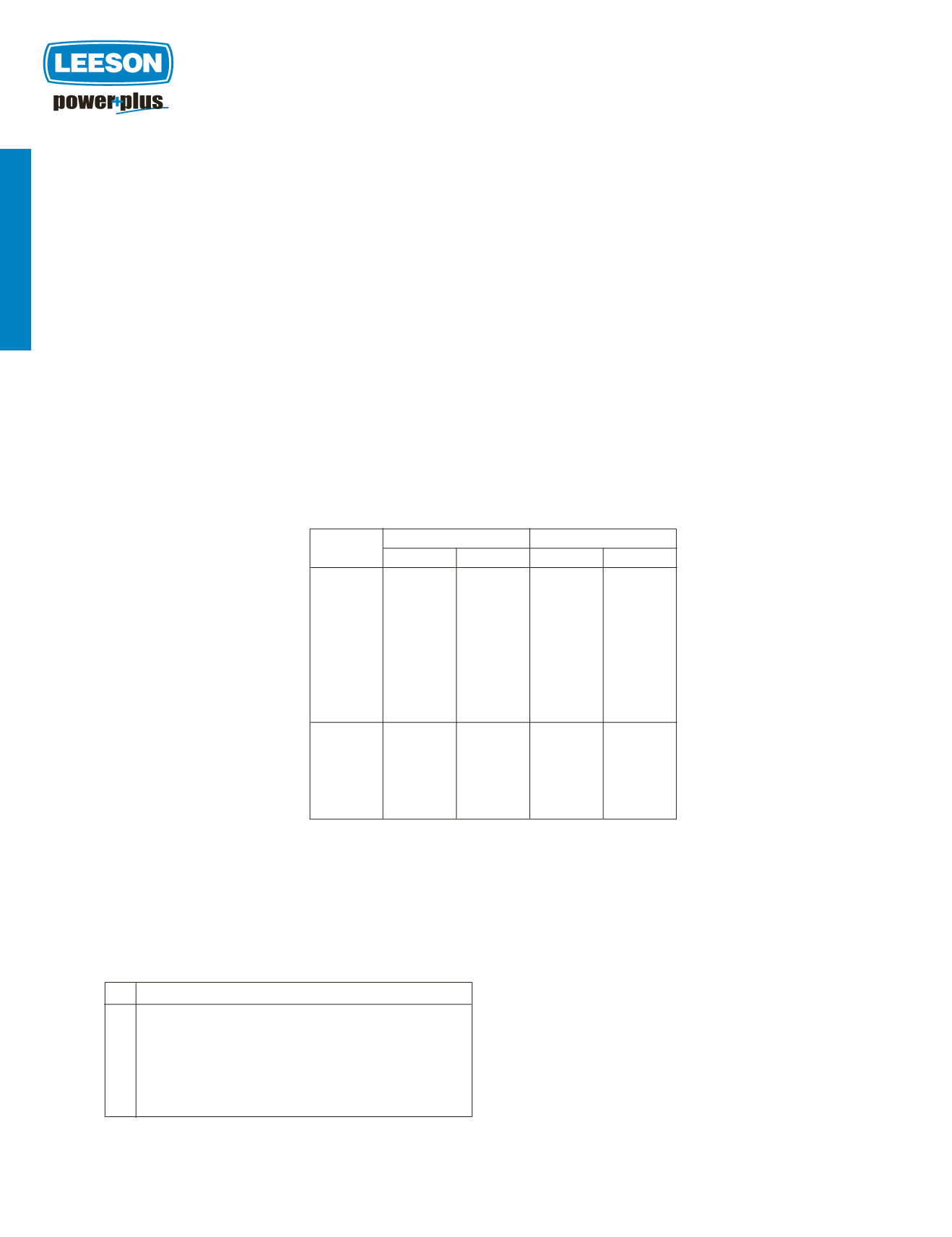

K

Load type

1.0 light loading start,work even

1.5 light loading start,work uneven

2.0 medium loading start,work even or uneven

2.5 light or heavy loading start,medium shock

3.0 lighty or heavy loading start,heavy shock or rotating

Type and load-bearing capacity

A bushing's load-bearing capacity is related with

tightening torque and shaft size and the load-bearing

capacity increases as the shaft size enlarges. If more

detailed information is required please contact

LEESON.

Torque capacity parameters and related screw

tightening torques in the table below:

IMPORTANT:

Screws must be tightened evenly. Over

tightening the screws may cause the hub or sheave

to crack.

TORQUE CAPACITY &

SCREW TIGHTENING TORQUE

BUSHINGS

SD/SDS 5,000 565 108 12.2

TM

®