SECTION

PAGE

DATE

USA: (937) 778-8947 • Canada: (905) 457-6223 • International: (937) 615-3598

A Crane Co. Company

Submersible Grinder Pumps

1

G

Professional Plumbing

Series PGPP, PGPH

ProGrind

, Vortex

DISCHARGE ...................................

1¼” NPT, Female, Vertical, Bolt-On Flange

LIQUID TEMPERATURE ...................

160°F (71°C) Intermittent

VOLUTE ............................................

Cast Iron ASTM A-48, Class 30

MOTOR HOUSING ............................

Cast Iron ASTM A-48, Class 30

SEAL PLATE ....................................

Cast Iron ASTM A-48, Class 30

LEGS..................................................

Removable and Adjustable

IMPELLERS:

Design

......................

12 Vane,Vortex, With Pump Out Vanes

On Back Side. Dynamically Balanced, ISO G6.3.

Material

.....................

Cast Iron ASTM A-48, Class 30

SHREDDING RING ...........................

Hardened 440C Stainless Steel, Rockwell® C-55.

CUTTER

............................................

Hardened 440CStainless Steel, Rockwell® C-55.

SHAFT

..............................................

416 Stainless Steel

SQUARE RINGS ...............................

Buna-N

HARDWARE ......................................

300 Series Stainless Steel

PAINT ................................................

Air Dry Enamel.

SEAL:

Design

.......................

Single Mechanical

Material

......................

Silicon-Carbide/Silicon-Carbide/Buna-N

Hardware -300 Series Stainless

CORD ENTRY ...................................

20 ft. (6m) Cord with plug Custom Molded

Quick Connect, for Sealing and Strain Relief

UPPER BEARING...............................

Single Row, Ball, Oil Lubricated

Load

..........................

Radial

LOWER BEARING

Single Row, Ball, Oil Lubricated

Load

...........................

Radial & Thrust

MOTOR:

Design

.......................

NEMA L-Single Phase Torque Curve,

Oil-Filled, Squirrel Cage Induction

Insulation

................

Class F

SINGLE PHASE.................................

Capacitor Start/Capacitor Run.

LEVEL CONTROL:

A Series

......................

Pipe Mounted, Piggy-Back, Mechanical

with 240 Plug

ACCESSORIES .................................

Break Away Fitting (BAF)

Check Valve

Control Panel

Series: PGPP & PGPH,

ProGrind

2HP, 3450RPM, 60Hz

DESCRIPTION:

THE GRINDER PUMP IS DESIGNED TO REDUCE

DOMESTIC, COMMERCIAL, INSTITUTIONAL AND LIGHT

INDUSTRIAL SEWAGE TO A FINELY GROUND SLURRY

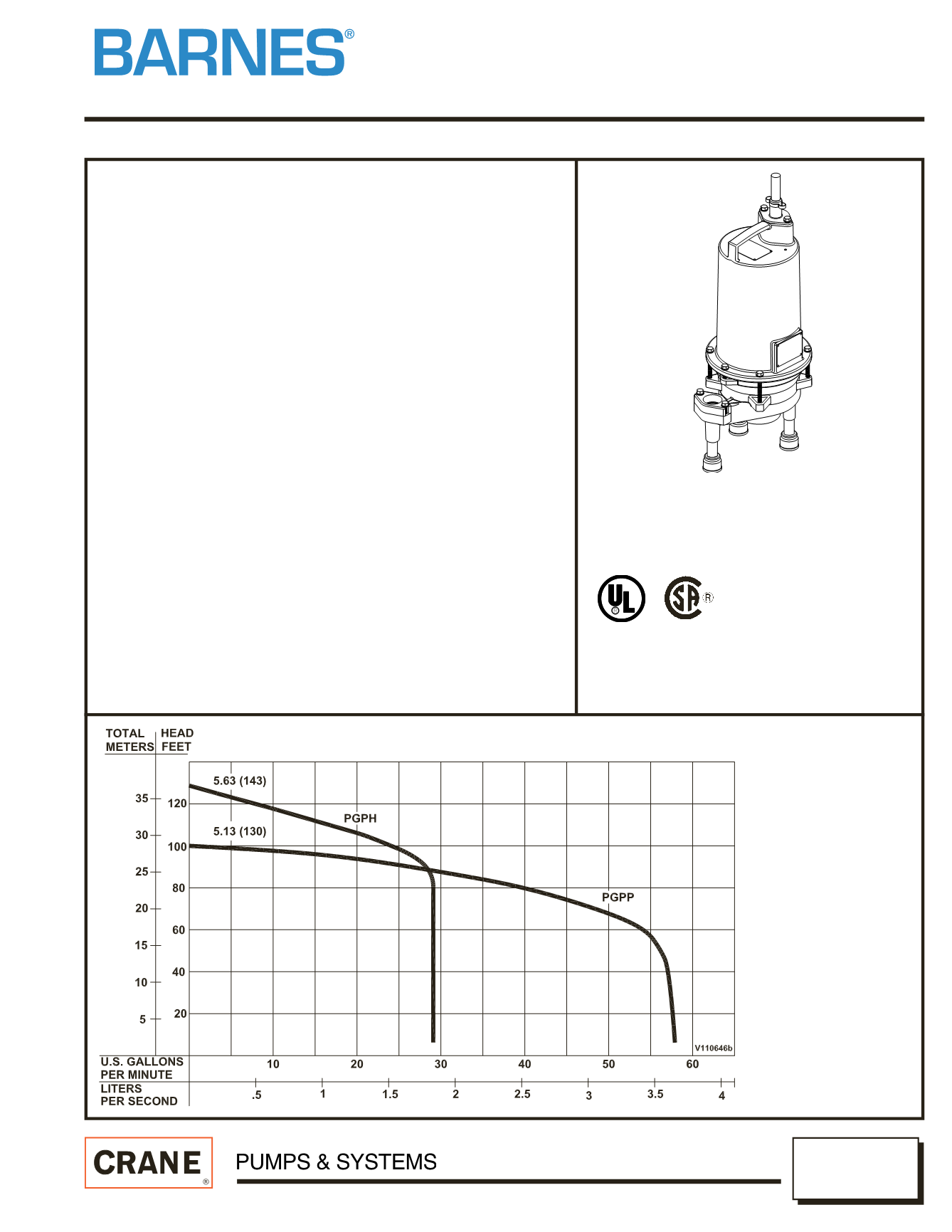

9/10

Testing is performed with

water specific gravity of 1.0

@ 68˚F (20˚C), other fluids

may vary performance