14

Informationa

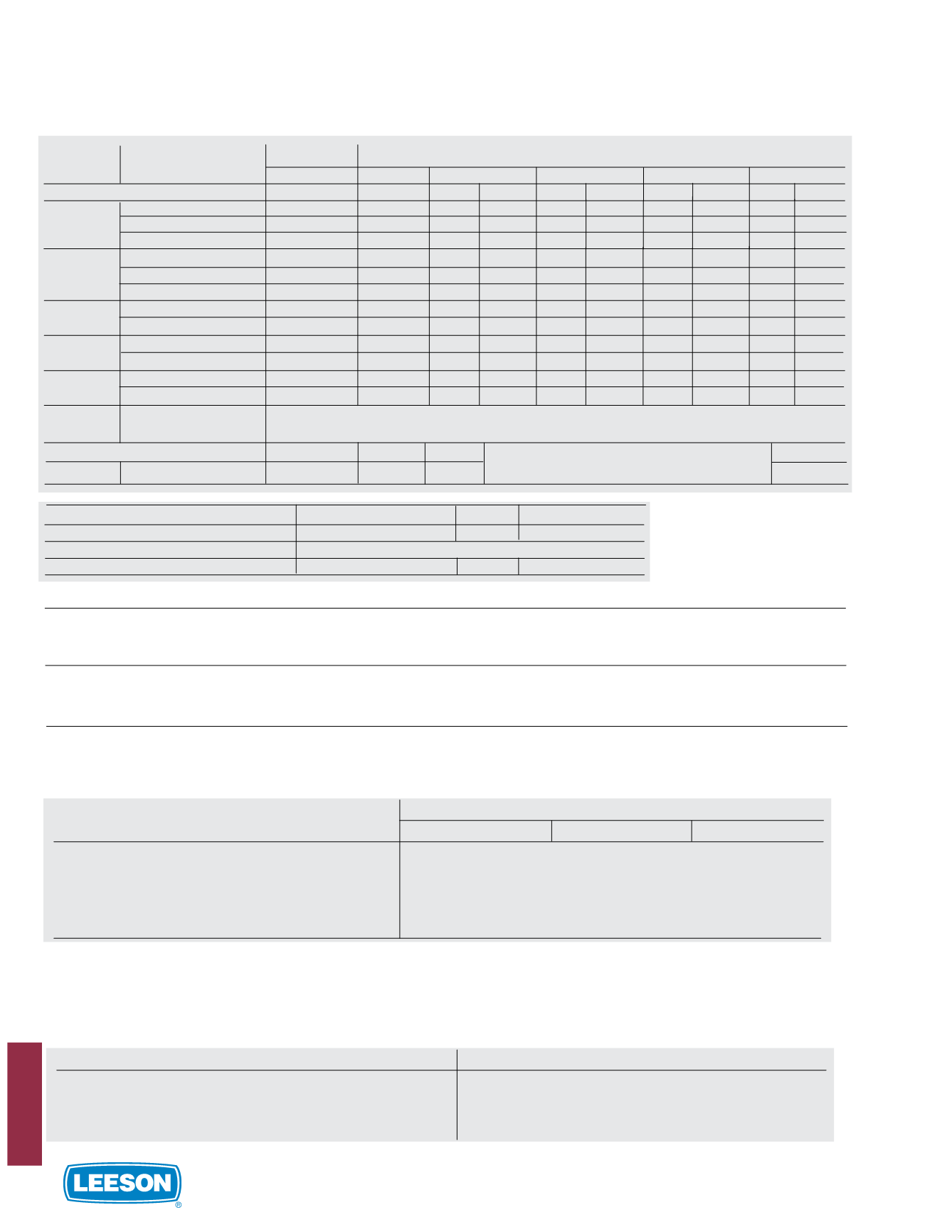

Variable Speed Operation

ENCLOSURE

EFFICIENCY

VARIABLE TORQUE

CONSTANT TORQUE

ALL FRAMES

56

143-215

254-286

324-365

404-449

NEMA Motors

ALL POLES

ALL POLES 2-Pole 4&6 Pole 2-Pole 4&6 Pole 2-Pole 4&6 Pole 2-Pole 4&6 Pole

Standard (EPAct exempt)

10:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

ODP

EPAct compliant

10:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

NEMA Premium

10:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

2:1

Standard (EPAct exempt)

10:1

2:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

TEFC

EPAct compliant

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

NEMA Premium

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

10:1

TENV

EPAct compliant

10:1

10:1

1000:1 1000:1 1000:1 1000:1 1000:1 1000:1 1000:1 1000:1

NEMA Premium

10:1

1000:1

1000:1 1000:1 1000:1 1000:1 1000:1 1000:1 1000:1 1000:1

Washdown Standard (EPAct exempt)

10:1

10:1

10:1

10:1

N/A

N/A

N/A

N/A

N/A

N/A

TEFC

Premium & EPAct compliant

10:1

10:1

10:1

10:1

N/A

N/A

N/A

N/A

N/A

N/A

Washdown Standard (EPAct exempt)

10:1

10:1

10:1

10:1

N/A

N/A

N/A

N/A

N/A

N/A

TENV

Premium & EPAct compliant

10:1

10:1

10:1

10:1

N/A

N/A

N/A

N/A

N/A

N/A

Explosion

All efficiency levels

Explosion Proof motors must be properly nameplated with inverter duty information prior to use on VFD.

Proof

Motors with automatic overload protectors cannot be used on VFDs.

IEC Motors

ALL FRAMES

63-90

100-250

Speedmaster

®

Inverter Duty/Vector Duty Motors ALL FRAMES

All Enclosures

All efficiency levels

10:1

20:1

Up to 20:1

& Lincoln CTAC

®

Motors

2000:1

Lincoln Rolled Steel

ODP-280-360 Frame

2:1

Constant Torque

280 Frame and Higher

TEFC-280-360 Frame

2:1

Constant Torque

400 Frame and Higher -

Contact Sales Office

Stock 90VDC and 180 VDC DC Motors

30:1

Rated Torque

Application Notes

Restricted use

DO NOT APPLY THE FOLLOWING MOTORS ON VARIABLE FREQUENCY DRIVES:

Single Phase motors, Motors with inherent overload protection, Multi-Speed motors, Motors with 1.0 Service Factor on sine wave power.

Fire Pump motors should not be used with variable frequency power supplies, due to the critical nature of these applications.

Hazardous Locations Consult with LEESON Electric when applying motors and drives into Hazardous Locations, either Division/Zone 1 or Division/Zone 2 areas.

UL and CSA policies prohibit the installation of bearing protection devices, such as shaft grounding brushes, rings or insulated bearings on

motors in Hazardous Locations.

Guidelines for Application of General Purpose, Three Phase, Single Speed Motors on Variable Frequency Drives Meets NEMA

MG1-2006 Part 30 and Part 31 Section 4.4.2 Unless stated otherwise, motor nameplates do NOT include listed speed range.

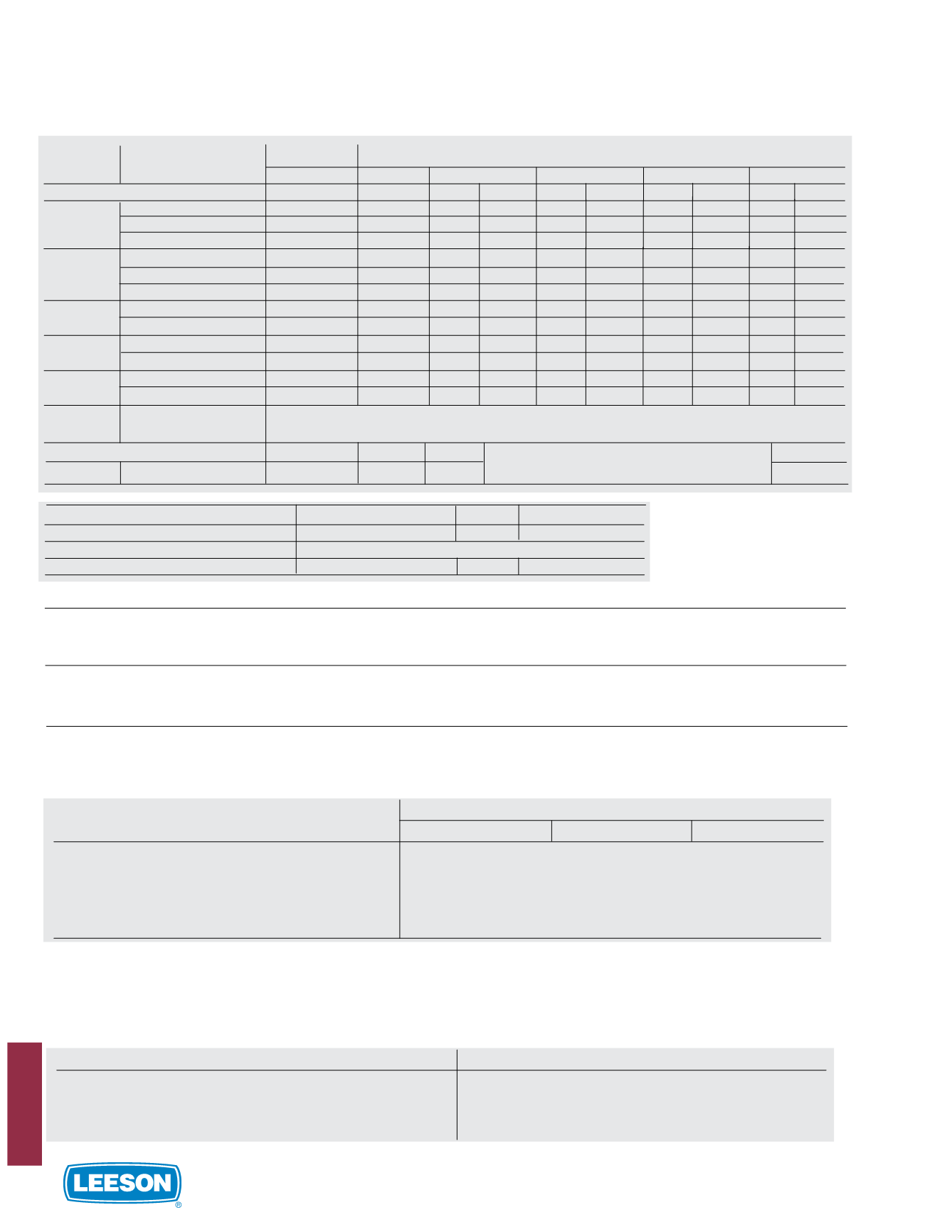

Maximum Cable Lengths from the Motor to Drive

* Higher carrier frequencies require shorter cable length to obtain normal (50Khrs) insulation life.

PRODUCT

3 kHz CARRIER FREQUENCY (PHASE TO PHASE)*

DESCRIPTION

230 VOLT

460 VOLT

575 VOLT

56-326 NEMA, 100-225 IEC Frames

600 ft.

125 ft.

40 ft.

364-5013 NEMA, 250-315 IEC Frames

1000 ft.

225 ft.

60 ft.

Motors with Corona Resistant Magnet Wire

1500 ft.

475 ft.

140 ft.

Motors with IRIS™ Insulation or Ultimate-e™ Spike Defense ™

Unlimited

Unlimited

650 ft.

Form-wound low voltage motors

Unlimited

Unlimited

650 ft.

Standard Motor Insulation Systems

IRIS™ INSULATION SYSTEM

ULTIMATE SPIKE DEFENSE™

All LEESON 3-Phase Motors 1HP and above.

Lincoln Motors Premium Efficient

All Premium Efficient WattSAVERe

®

Motors

Lincoln Inverter Duty

CTAC

®

Motors