Specifications are subject to change without notice

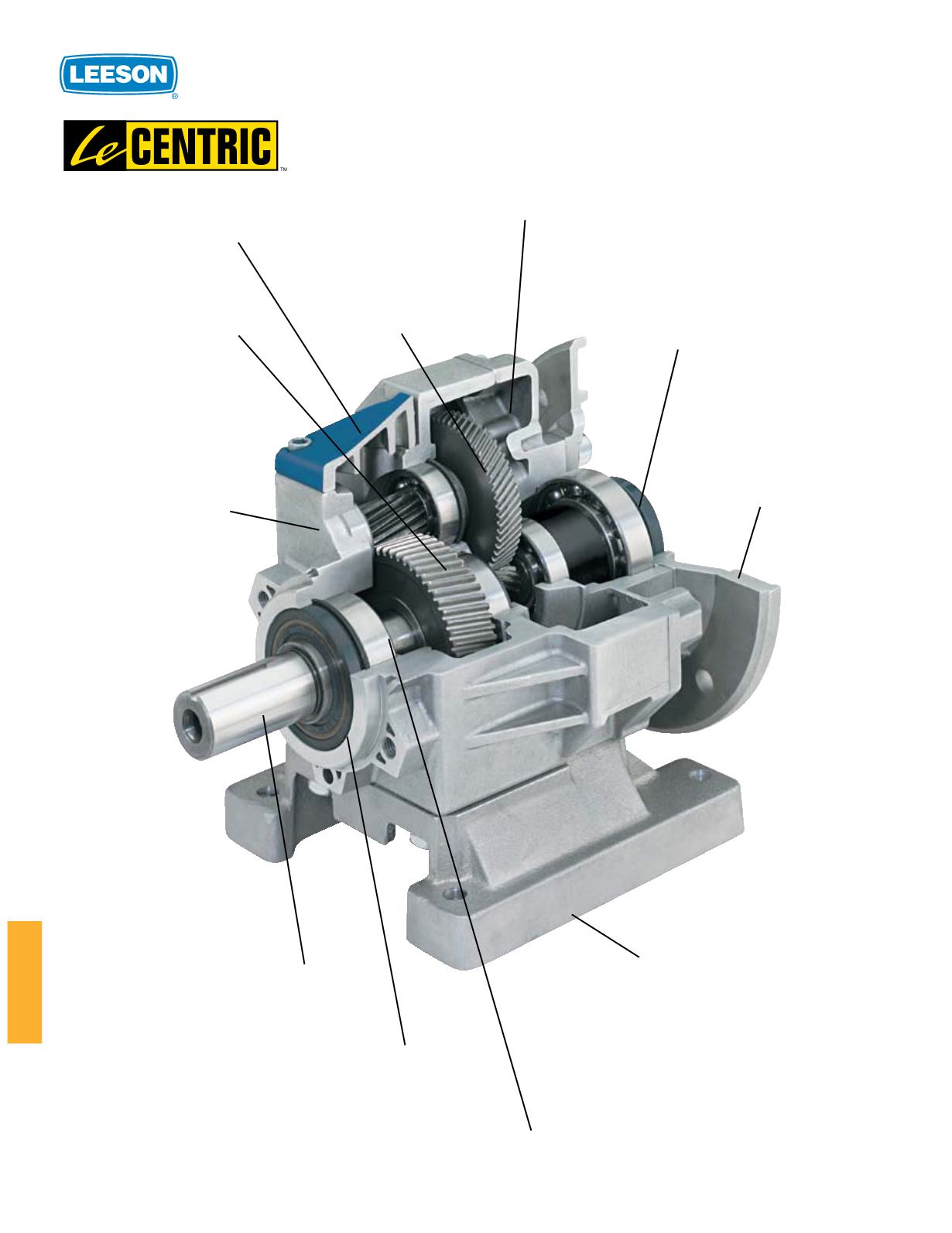

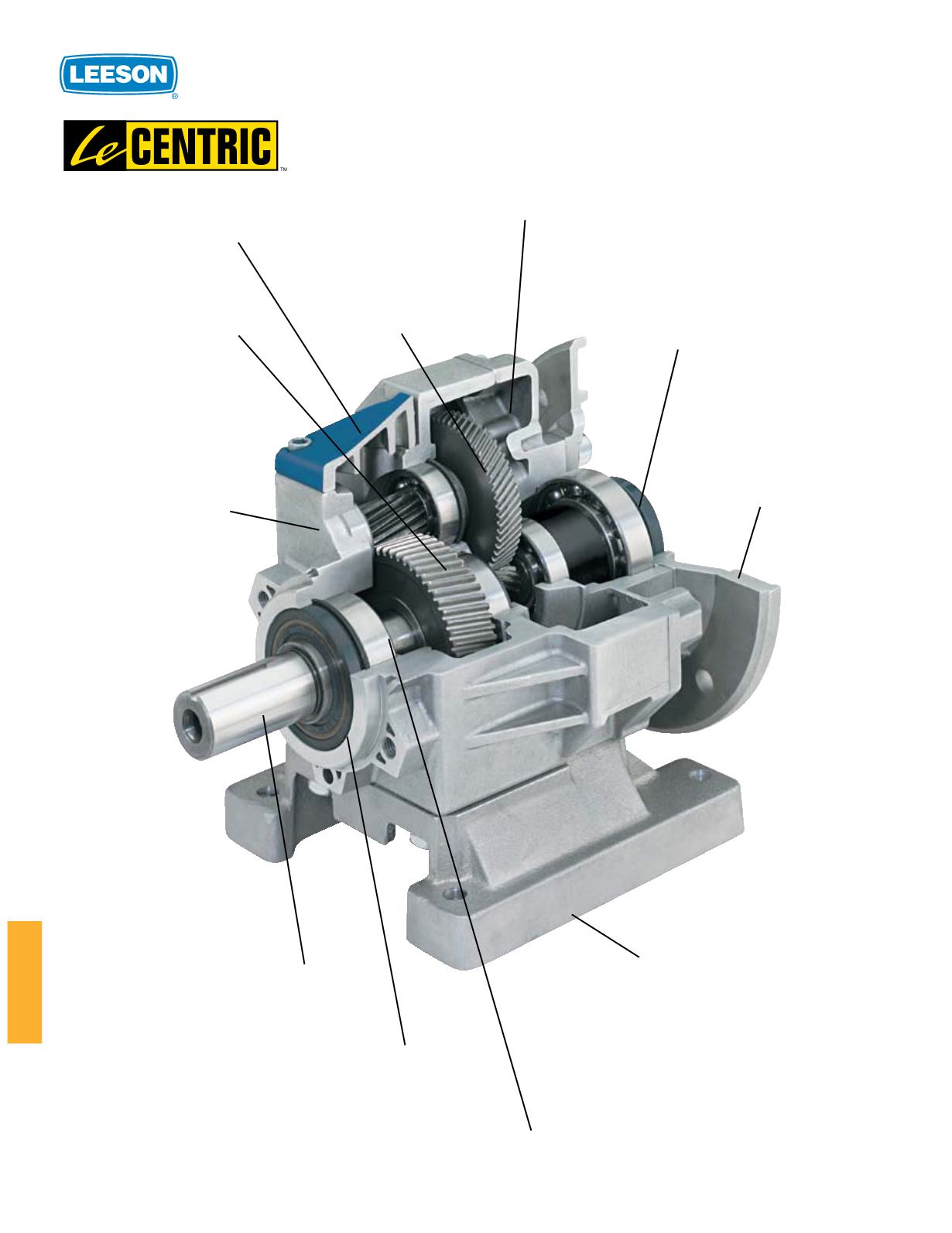

Gearing

LeCENTRIC

™

REDUCERS ARE FILLED WITH

MOBILGEAR SHC 320 SYNTHETIC OIL

(or

equivalent) as standard. All sizes are

considered “lubed for life.” Specify

mounting position at time of order. Refer

to page 60 for available positions.

REMOVABLE MOUNTING BASE

allows interchange with dozens of

competitive units.

BOLT-ON OUTPUT FLANGE

also

available to allow interchange with

many industry-standard sizes.

ALUMINUM NEMA C

FACE

input flange

(motorized quill

input models) with

machined fits for

precision alignment of

motor and bearings.

BEARING SPANS OPTIMIZED

to

allow for maximum overhung

load capacity, enhanced

durability and reliability—while

minimizing shaft deflection.

SINGLE-PIECE ALUMINUM ALLOY HOUSING

vacuum impregnated with Resinol

RT (MIL-STD 276) for protection and

sealing. No secondary finish required

but readily accepts paint. Combines

light weight with high tensile strength.

Precision machined for alignment of

bearings and gearing.

PREMIUM VITON

®

SEALS

provide extra

protection against entry of contaminants

or loss of lubrication. Tandem seals

available on input and output.

ALL GEARING IS HARDENED AND

GROUND

(AGMA Class 10 or

better), for enhanced efficiency and

noise reduction. Double reduction

units are 96 – 97% efficient.

MOUNTING DIMENSIONS ARE

INTERCHANGEABLE

with many popular

reducers, including SEW, David Brown,

Nord, Dodge, and Brook Hansen.

ROBUST OUTPUT SHAFT

of high strength

steel alloy for superior torque and

overhung load capacities.

REMOVABLE INSPECTION COVER

allows

periodic inspection of gearing during

routine maintenance.

OVERSIZED BALL BEARINGS

on both input and output shafts.

RATIOS UP TO 63:1

in two-stage

units and up to 278:1 in three-

stage units to maximize efficiency

and reduce overall case size.

PERMANENTLY MARKED NAMEPLATE

with

output torque, ratio and maximum input

horsepower.

LeCENTRIC REDUCERS