Specifications are subject to change without notice

AC Motors

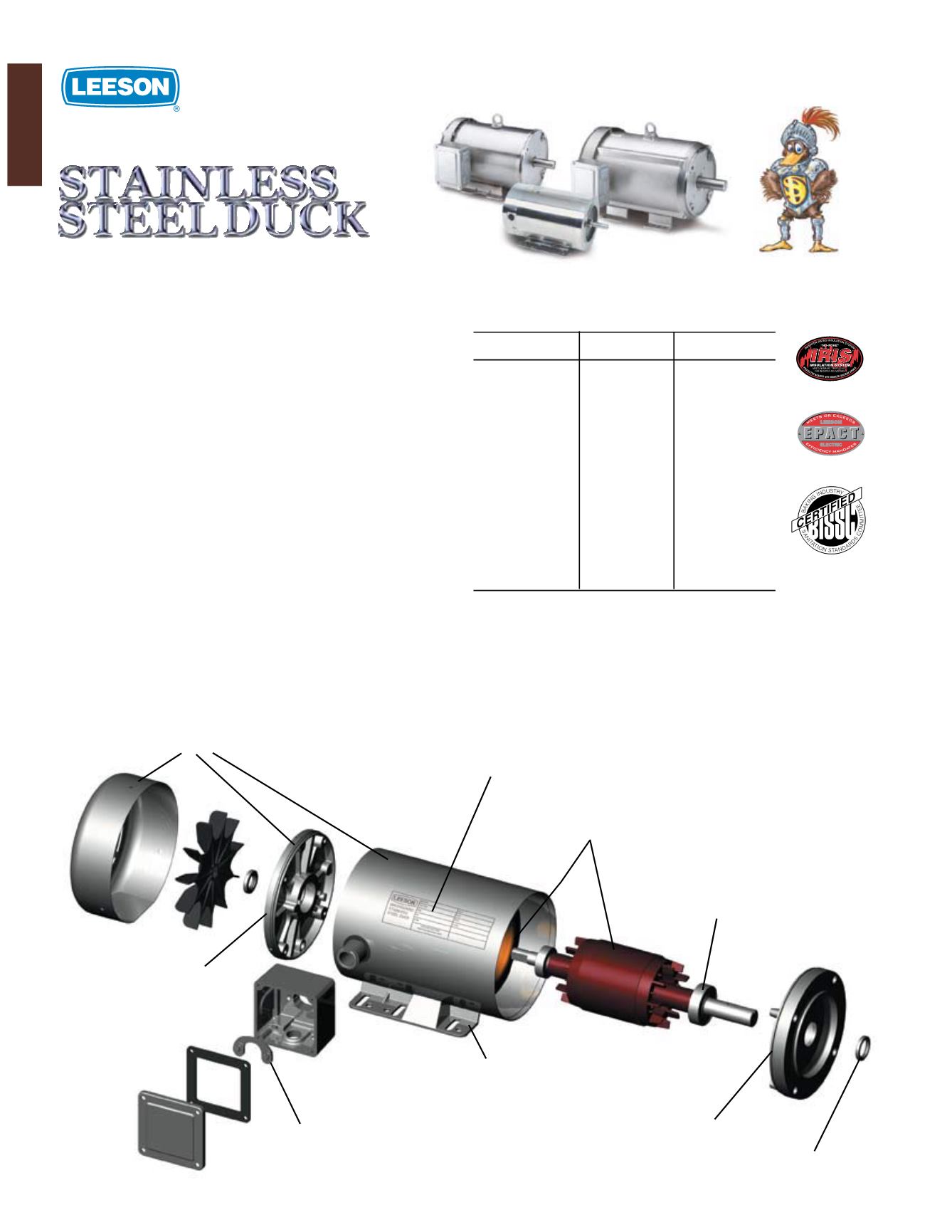

Viton

®

O-rings

seal the fit between

the frame and endshields to exclude

moisture and resist harsh chemicals

Viton

®

double-lip

shaft seals

on both

ends of TEFC motors.

Hydrophobic breathers

in opposite endshield and

conduit box allow passage of

air for pressure equalization

without allowing moisture to

enter the motor.

Double-sealed bearings

with moisture-

resistant high-temperature grease.

Revolutionary conduit box

mounting

uses pressure clip

to assure maximum sealing and

allows easy repositioning for

multiple conduit entry locations.

Fillet welded base

is double-welded for greatest

strength.

Extra strong cast stainless steel base

on

motors over 1HP.

CHEMICAL RESISTANCE RATING CHART

ALL STAINLESS

CHEMICAL

CONCENTRATION COMPONENTS

WATER:

De-Ionized Boiling

100%

Excellent

Salt (Immersed)

30%

Excellent

Salt (Spray)

5%

Excellent

Tap - 250°F/120°C @

100%

Excellent

10,000 PSI

ACIDS:

Hydrochloric

35%

Poor

Sulfuric

25%

Poor

Nitric

35%

Excellent

Picric

Saturated Solution

Excellent

BASE:

Caustic

100%

Excellent

Caustic

12.5 pH

Excellent

Caustic - 125°F/50°C

9.5 pH

Excellent

SOLVENTS:

–

Excellent

PREMIUM

Laser-etched

full-fact nameplate on

motor frame.

Interior coatings

applied to rotor and stator

protect against moisture and corrosion.

300-Series stainless steel

exterior components – frame, base, endshields, shaft extension, fan guard,

hardware, conduit box and cover – for maximum corrosion resistance.

General Specifications:

Motors have been tested to and passed the IEC IP-56 test requirements. Designed specifically to meet the demanding sanitation requirements of the pharmaceutical,

food processing and beverage industries. These motors are also ideal in clean room and severe chemical-processing applications involving frequent washdown

WITH NITRIC ACID AND CAUSTIC LYE )N FACT 7!3('5!2$ !LL 3TAINLESS -OTORS INCLUDE )%%% SEVERE DUTY FEATURES RIGHT OUT OF THE BOX

Mechanical Protection Features:

s !LL EXTERIOR COMPONENTS ARE SERIES STAINLESS STEEL

s .OTHING ON THE MOTOR S EXTERIOR IS PAINTED OR COATED IN ANY WAY

s !LL SEALING COMPONENTS ARE 6ITON

®

for superior chemical resistance.

s &ULL FACT NAMEPLATE IS LASER ETCHED ON THE MOTOR FRAME n NO SEPARATELY

attached nameplate to trap dirt or contaminants.

s %NDSHIELDS ARE / RING SEALED TO THE FRAME

s $OUBLE LIP SHAFT SEALS ON BOTH ENDS OF 4%&# MOTORS SHAFT END ONLY ON

TENV motors).

s 2EMOVABLE HYDROPHOBIC BREATHERS IN OPPOSITE SHAFT ENDBELL AND CONDUIT BOX

equalize pressure without allowing moisture to enter.

s %XTERIOR FASTENER USE MINIMIZED REDUCING THE NUMBER OF ENTRY POINTS FOR

moisture. There are no holes in the frame for attaching a nameplate. Bearing

LOCK SCREWS ARE LOCATED INSIDE THE MOTOR AND THE CONDUIT BOX MOUNTED SCREWS

have been eliminated.

s $OUBLE SEALED BEARINGS ARE PRE LUBRICATED WITH MOISTURE RESISTANT HIGH

temperature grease for long life.

s )NTERIOR COATINGS APPLIED TO ROTOR AND STATOR PROTECT AGAINST CORROSION

s .EW CONDUIT BOX MOUNTING SYSTEM PROVIDES OPTIMUM SEALING

s %ASE TO CLEAN CONSTRUCTION IS ")33# #ERTIFIED FOR BAKERY APPLICATIONS

Electrical Performance and Protection Features

s 7!3('5!2$ EFFICIENCIES MEET %0!#4 MANDATES FOR NON EXEMPT MOTORS WHEN TESTED WITHOUT SHAFT SEALS

s 7INDINGS ARE IMMERSED AND CURED IN POLYESTER INSULATING VARNISH FOR EXTRA MOISTURE RESISTANCE

s ,%%3/. S EXCLUSIVE )2)3

™

Inverter-Rated Insulation System provides extra protection and long life, especially in inverter-driven applications.

s 3INGLE PHASE MOTORS USE 3OLID 3TATE 3INPAC

®

switch – no mechanical switch contacts to corrode and fail.

Standards and Approvals

s 3INGLE AND THREE PHASE MOTORS ARE 5, COMPONENT RECOGNIZED n FILE NUMBER %

GUIDE NUMBER 02'9

s #3! %NERGY %FFICIENCY 6ERIFICATION 0ROGRAM REPORT NUMBER %%6

s #ONSTRUCTION IS #3! #ERTIFIED FOR SAFETY REPORT NUMBER ,2 AND LISTED UNDER ")33# AUTHORIZATION NUMBER

44

7!3('5!2$

™

!,, 34!).,%33 -/4/23

!,, 34!).,%33 s 3).',% 0(!3% s 4(2%% 0(!3%