Specifications are subject to change without notice

AC Motors

50

8* "- " *,"" Ê "/",-ÊUÊxÇxÊ6" /-

4(2%% 0(!3% s #!34 )2/.

EXPLOSION-PROOF

FOR HAZARDOUS LOCATIONS

5NDERWRITERS ,ABORATORIES

AND #ANADIAN 3TANDARDS

!SSOCIATION ,ISTED

'ENERAL 3PECIFICATIONS

These explosion proof motors are

designed and approved for application

in hazardous environments having

certain explosive gases or materials

present.

&EATURES

Rugged mechanical construction meeting all requirements for

safety. UL and CSA listed.

Double shielded, pre-lubricated ball bearings are standard. All

motors have inherent automatic overload protection.

NEMA 1.0 service factor on CX Series.

.%-! SERVICE FACTOR ON ' 3ERIES

Explosion-proof NEC-size conduit box included at no extra cost.

Normally-closed thermostats are standard.

!PPLICATION .OTES

These motors must be applied in accordance with the National

Electrical Code, Article #500. A partial listing of explosive agents

is noted below. Consult NFPA Publication 497M for a complete

LISTING .O ,%%3/. -OTORS ARE LISTED FOR #LASS ) 'ROUPS ! OR "

Please note headings and footnotes for qualifications of specific

LEESON motors.

#LASS )

'ROUP !

Acetylene

'ROUP "

Butadiene, ethylene oxide, hydrogen, propylene

oxide, manufactured gases containing more than 30% hydrogen

by volume.

'ROUP #

Acetaldehyde, cyclopropane, diethyl ether, ethylene.

'ROUP $

Acetone, acrylonitrile, ammonia, benzene, butane,

ethanol, ethylene dichloride, gasoline, hexane, isoprene, methane

(natural gas), methanol, naphtha, propane, propylene, styrene,

toluene, vinyl acetate, vinyl chloride, xylene.

#LASS ))

'ROUP %

Aluminum, magnesium and other metal dusts with similar

characteristics.

'ROUP &

#ARBON BLACK COKE OR COAL DUST

'ROUP '

Flour, starch or grain dust.

Normally-closed thermostats.

, Ê - ÊUÊ/ , Ê* - ÊUÊ -/Ê ," Ê , ÊÊ

--Ê ]Ê ,"1*Ê ÊEÊ Ê—

--Ê ]Ê ,"1*-Ê ÊEÊ ÊUÊ7 / Ê " 1 /Ê "8Ê

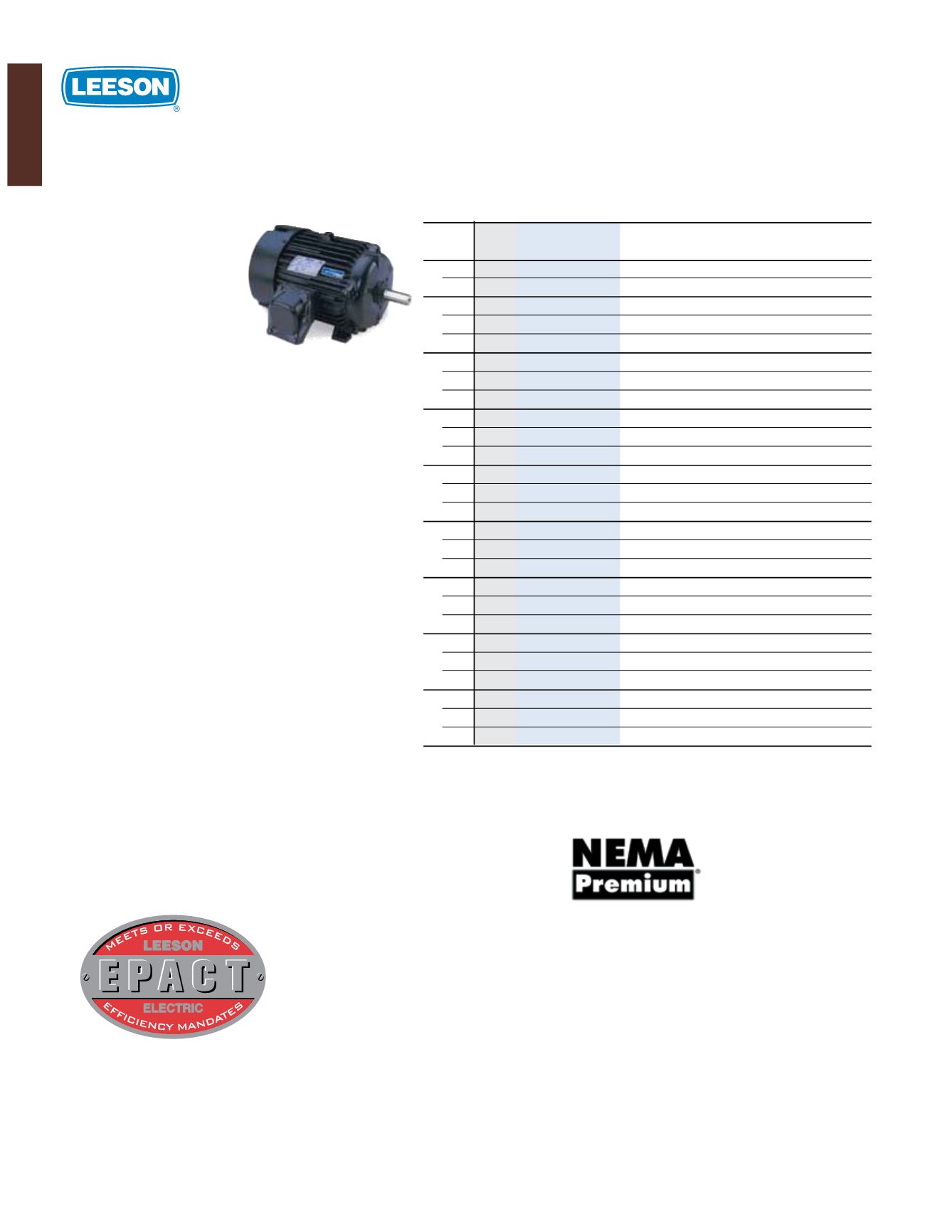

RPM

App.

F.L.

%

“C”

60

NEMA

Catalogue

Wgt.

Amps

F.L.

Dim.

HP

Hz

Frame

Number

(lbs.)

Voltage

575 V.

Eff.

(Inches)

3

1800 182T

850686

91

575

3.2

89.5

17.12

1200 213T

850687

138

575

3.5

89.5

20.18

5

3600 184T

850688

125

575

5.0

88.5

17.12

1800 184T

850689

125

575

5.0

89.5

17.12

1200 215T

850690

155

575

5.5

89.5

20.18

7

1

⁄

2

3600 213T

850691

138

575

7.6

89.5

20.18

1800 213T

850692

138

575

8.0

91.7

20.18

1200 254T

850693

238

575

8.2

91.0

23.52

10

3600 215T

850694

155

575

9.6

90.2

20.18

1800 215T

850695

155

575

10.4

91.7

20.18

1200 256T

850696

263

575

10.4

91.0

23.52

15

3600 254T

850697

238

575

14.4

91.0

23.52

1800 254T

850698

238

575

15.6

92.4

23.52

1200 284T

850699

365

575

16.0

91.7

26.30

20

3600 256T

850700

263

575

18.4

91.0

25.27

1800 256T

850701

263

575

20.0

93.0

25.27

1200 286T

850702

385

575

21.6

91.7

27.80

25

3600 284TS

850703

365

575

23.2

91.7

24.94

1800 284T

850704

366

575

25.2

93.6

26.30

1200 324T

850705

550

575

26.8

93.0

28.87

30

3600 286TS

850706

385

575

28.0

91.7

26.44

1800 286T

850707

385

575

29.6

93.6

27.80

1200 326T

850708

570

575

32.8

93.0

30.37

40

3600 324TS

850709

546

575

36.8

92.4

27.37

1800 324T

850710

550

575

41.2

94.1

28.87

1200 364T

850711

875

575

40.0

94.1

31.50