46

Specifications are subject to change without notice

AC Motors

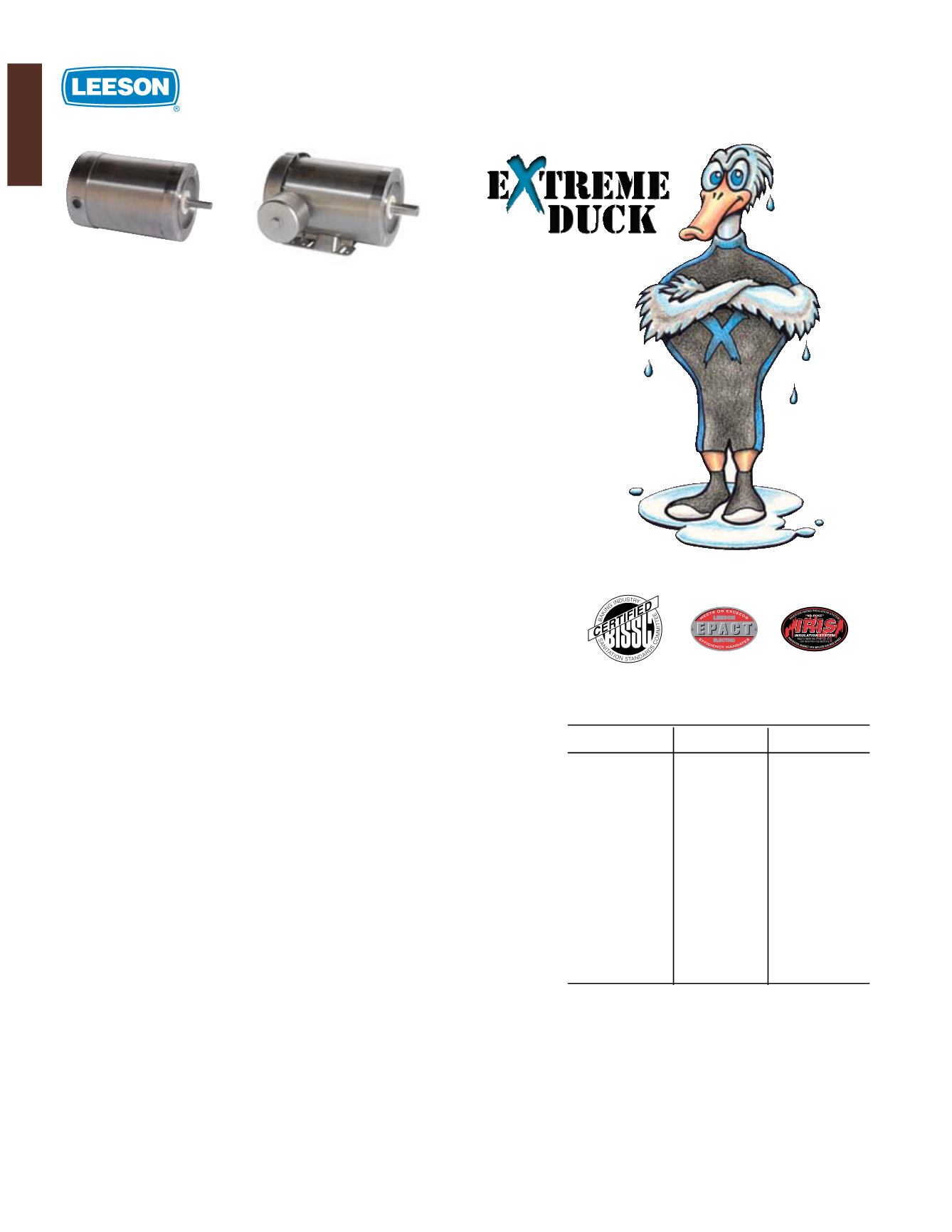

CHEMICAL RESISTANCE RATING CHART

ALL STAINLESS

CHEMICAL

CONCENTRATION COMPONENTS

WATER:

De-Ionized Boiling

100%

Excellent

Salt (Immersed)

30%

Excellent

Salt (Spray)

5%

Excellent

Tap - 250°F/120°C @

100%

Excellent

10,000 PSI

ACIDS:

Hydrochloric

35%

Poor

Sulfuric

25%

Poor

Nitric

35%

Excellent

Picric

Saturated Solution

Excellent

BASE:

Caustic

100%

Excellent

Caustic

12.5 pH

Excellent

Caustic - 125°F/50°C

9.5 pH

Excellent

SOLVENTS:

–

Excellent

7!3('5!2$ !,, 34!).,%33 -/4/23

!,, 34!).,%33 s 4(2%% 0(!3% s 34!.$!2$ .%-! 02%-)5- 2!4).'3

General Specifications:

These Revolutionary Designed Stainless Steel Motors are built using our “Voice of the

customer” design criteria to withstand extreme washdown and sanitation requirements of

THE FOOD PROCESSING PHARMACEUTICAL PACKAGING AND BEVERAGE INDUSTRIES /UR )NNOVATIVE

Hydro Sealed System “HS

2

™” protects from the “outside-in” by reducing entrance points of

contaminants and eliminates the need for drain plugs and breathers. This proven process also

minimizes exterior hardware, which may trap application elements. Our unique Rotor/Cartridge

3EAL 3YSTEM h1 #!2v GIVES QUICK ACCESS TO THE INTERIOR OF THE MOTOR SHOULD THE NEED ARISE

300-Series Stainless Steel used on all exterior surfaces gives ideal protection against severe

chemical-processing applications and frequent washdown processes using Salt water, Nitric

Acids and Solvents.

Mechanical Protection Features:

s !LL EXTERIOR COMPONENTS ARE 3ERIES STAINLESS STEEL

s 0ROTECH "EARING ISOLATOR USED FOR THE OUTPUT SHAFT SEAL

s $OUBLE ,IP 6ITON SHAFT SEAL USED ON NON DRIVE OUTPUT SHAFT ON 4%&# MOTORS

s -INIMAL EXTERIOR FASTENERS DUE TO NO THROUGH BOLT DESIGN AND SCREW ON CONDUIT BOX COVERS

reduces surface areas that may trap contaminants

s $OUBLE SEALED BEARINGS ARE PRE LUBRICATED WITH MOISTURE RESISTANT HIGH TEMPERATURE GREASE

for long life

s 2OTOR #ARTRIDGE h1 #!2 v DESIGN FOR QUICK ACCESS TO MOTOR INTERIOR PATENT PENDING

s / RING SEALED OPENINGS ON CONDUIT BOX COVERS AND 2OTOR #ARTRIDGE COVER

s 2IGID #AST "ASE FOR RUGGED APPLICATIONS

s #ONDUIT BOX LEAD HOLE LOCATION ROTATABLE ON 4%&# DESIGNS

s &ULL FACT NAMEPLATE IS LASER ETCHED TO THE MOTOR FRAME MAKING FRAME SURFACE SMOOTH WHICH

eliminates areas that trap contaminants

s %ASE OF CLEAN CONSTRUCTION IS ")33# CERTIFIED FOR BAKERY APPLICATIONS AND MOTORS MEET

Pharmaceutical Duty specifications

s )0 %NCLOSURE PROTECTION

Electrical Performance and Protection Features

s -OTORS MEET %0!#4 MANDATES FOR NON EXEMPT MOTORS WHEN TESTED WITHOUT SHAFT SEALS

s 4OTAL WINDING ENCAPSULATION USING AN %POXY 2ESIN

s ,%%3/. S EXCLUSIVE )2)3 )NVERTER 2ATED )NSULATION 3YSTEM PROVIDES EXTRA PROTECTION AND

long life, especially when used in applications driven by an Inverter.

s YEAR WARRANTY

s

CONSTANT TORQUE OPERATION

Standards and Approvals

s -OTORS ARE 5, COMPONENT RECOGNIZED n FILE NUMBER %

GUIDE NUMBER 02'9

s #3! %NERGY %FFICIENCY 6ERIFICATION 0ROGRAM REPORT NUMBER %%6

s #ONSTRUCTION IS #3! #ERTIFIED FOR SAFETY REPORT NUMBER ,2 AND LISTED UNDER ")33#

authorization number 769

s YEAR WARRANTY