111

Specifications are subject to change without notice

Gearmotors

, / Ê ÊUÊ "7Ê6" / Ê£Ó6®

/ 6ÊUÊ£°äÊ- ,6 Ê

/",Ê

Full

Over-

DIMENSIONS

F.L.

Gearmotor

Arm Load

hung

Output Torque Input

Catalogue

Type &

Ratio Volts Amps. Load

P

PB

X

XL

XH

RPM (In.-Lbs.) HP

Number

Frame

to 1

DC

DC

(lbs.)

Inches

42

80

1

⁄

8

M1135249

13F60-34 60 12 11.0 235 3.38 4.21 4.50 10.39 5.89

250

25

1

⁄

8

M1135250

13F10-34 10 12 11.0 235 3.38 4.21 4.50 10.39 5.89

62

135

1

⁄

4

M1135251

13F40-34 40 12 21.0 235 3.38 4.21 4.50 12.64 8.14

125

90

1

⁄

4

M1135252

13F20-34 20 12 21.0 235 3.38 4.21 4.50 12.64 8.14

, / Ê ÊUÊ- ,Ê, /

/ 6ÊUÊ£°äÊ- ,6 Ê

/",

Full

Over-

DIMENSIONS

F.L.

Gearmotor

Arm Load

hung

Output Torque Input

Catalogue

Type &

Ratio Volts Amps. Load

P

PB

X

XL

XH

RPM (In.-Lbs.) HP

Number

Frame

to 1

DC

DC

(lbs.)

Inches

42

22

1

⁄

17

M1115018

10F60-25D 60 90 1.00 185 2.50 3.00 3.60 8.79 5.19

62

19

1

⁄

17

M1115019

10F40-25D 40 90 1.00 185 2.50 3.00 3.60 8.79 5.19

125

16

1

⁄

17

M1115020

10F20-25D 20 90 1.00 185 2.50 3.00 3.60 8.79 5.19

250

10

1

⁄

17

M1115021

10F10-25D 10 90 1.00 185 2.50 3.00 3.60 8.79 5.19

500

5

1

⁄

17

M1115022

10F05-25D 5

90 1.00 185 2.50 3.00 3.60 8.79 5.19

42

30

1

⁄

12

M1135053

13F60-34A 60 180 0.53 235 3.38 4.00 4.50 9.64 5.14

62

35

1

⁄

12

M1135054

13F40-34A 40 180 0.53 235 3.38 4.00 4.50 9.64 5.14

125

18

1

⁄

12

M1135055

13F20-34A 20 180 0.53 235 3.38 4.00 4.50 9.64 5.14

250

10

1

⁄

12

M1135056

13F10-34A 10 180 0.53 235 3.38 4.00 4.50 9.64 5.14

500

5

1

⁄

12

M1135057

13F05-34A 5 180 0.53 235 3.38 4.00 4.50 9.64 5.14

42

80

1

⁄

8

M1135069

13F60-34C 60 90 1.40 235 3.38 4.00 4.50 10.64 6.14

62

70

1

⁄

8

M1135038

13F40-34C 40 90 1.40 235 3.38 4.00 4.50 10.64 6.14

62

70

1

⁄

8

M1135058

13F40-34C 40 180 0.70 235 3.38 4.00 4.50 10.64 6.14

125

45

1

⁄

8

M1135039

13F20-34C 20 90 1.40 235 3.38 4.00 4.50 10.64 6.14

125

45

1

⁄

8

M1135059

13F20-34C 20 180 0.70 235 3.38 4.00 4.50 10.64 6.14

250

25

1

⁄

8

M1135040

13F10-34C 10 90 1.40 235 3.38 4.00 4.50 10.64 6.14

250

25

1

⁄

8

M1135060

13F10-34C 10 180 0.70 235 3.38 4.00 4.50 10.64 6.14

500

13

1

⁄

8

M1135041

13F05-34C 5

90 1.40 235 3.38 4.00 4.50 10.64 6.14

500

13

1

⁄

8

M1135061

13F05-34C 5 180 0.70 235 3.38 4.00 4.50 10.64 6.14

62

135

1

⁄

4

M1135042

13F40-34G 40 90 2.30 235 3.38 4.00 4.50 12.64 8.14

62

135

1

⁄

4

M1135062

13F40-34G 40 180 1.30 235 3.38 4.00 4.50 12.64 8.14

83

125

1

⁄

4

M1135043

13F30-34G 30 90 2.30 235 3.38 4.00 4.50 12.64 8.14

83

125

1

⁄

4

M1135063

13F30-34G 30 180 1.30 235 3.38 4.00 4.50 12.64 8.14

125

90

1

⁄

4

M1135044

13F20-34G 20 90 2.30 235 3.38 4.00 4.50 12.64 8.14

125

90

1

⁄

4

M1135064

13F20-34G 20 180 1.30 235 3.38 4.00 4.50 12.64 8.14

250

50

1

⁄

4

M1135045

13F10-34G 10 90 2.30 235 3.38 4.00 4.50 12.64 8.14

250

50

1

⁄

4

M1135065

13F10-34G 10 180 1.30 235 3.38 4.00 4.50 12.64 8.14

500

30

1

⁄

4

M1135046

13F05-34G 5

90 2.30 235 3.38 4.00 4.50 12.64 8.14

500

30

1

⁄

4

M1135066

13F05-34G 5 180 1.30 235 3.38 4.00 4.50 12.64 8.14

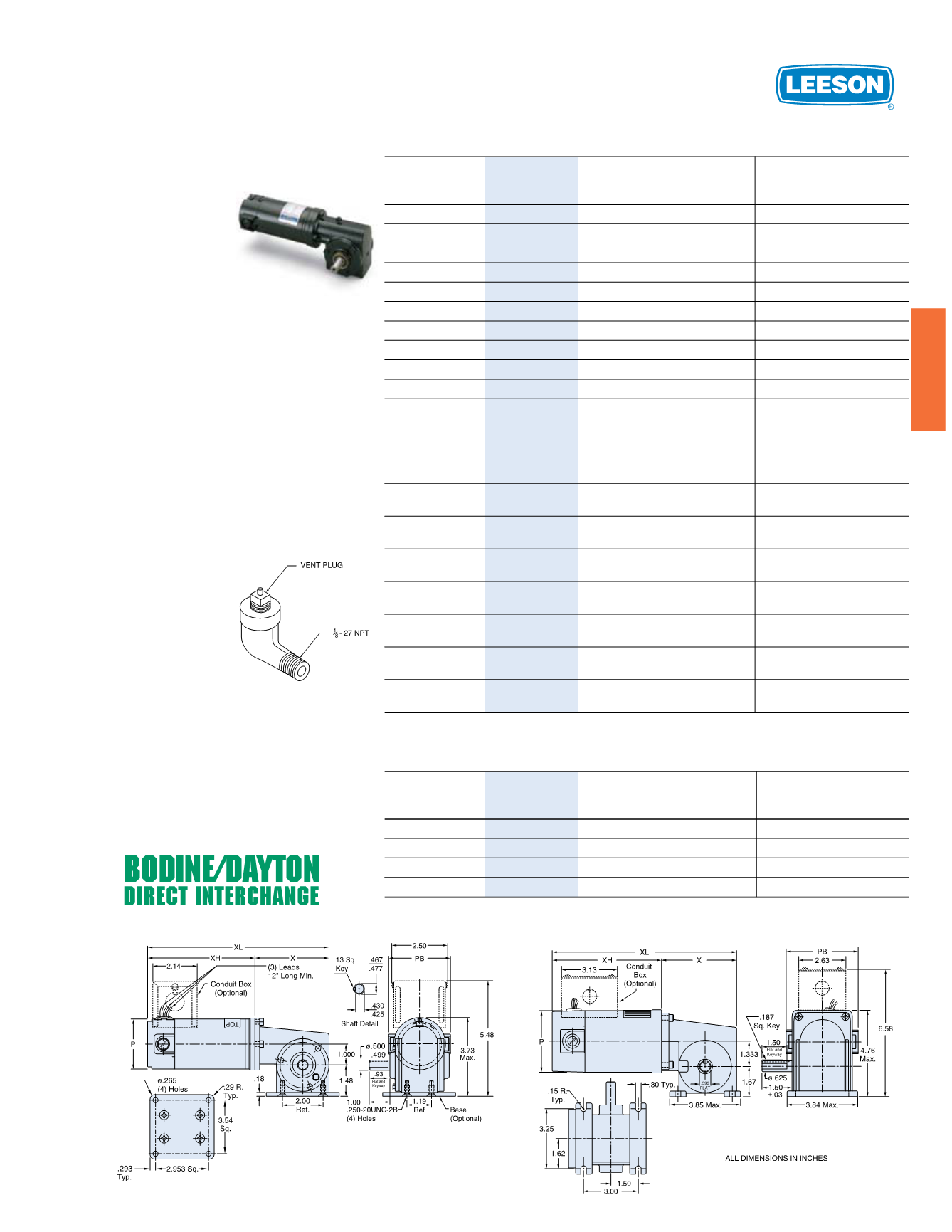

SUB-FHP DC GEARMOTORS

RIGHT ANGLE SHAFT GEARMOTORS

SCR RATED:

5-135 In-Lbs Torque

LOW VOLTAGE:

25-135 In-Lbs Torque

Electrical Specifications:

SCR Rated Gearmotors

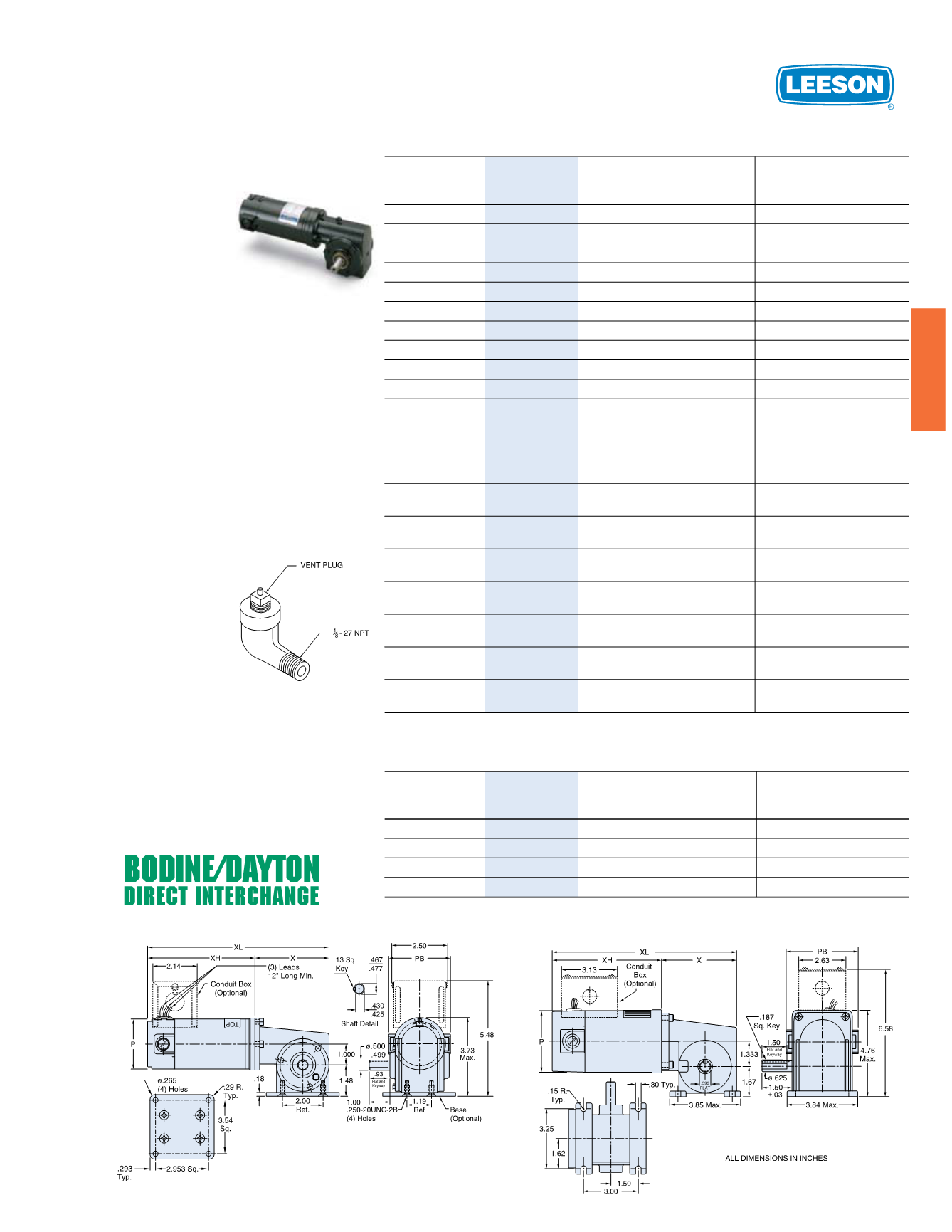

Totally enclosed right-angle

gearmotors, performance

matched for continuous

service over a 60:1 speed

range. All have constant torque

throughout the range when powered by a

full-wave, unfiltered SCR-type 115 volt input adjustable

speed control having a typical form factor of 1.3 to 1.4.

Also available as factory options are motors for low

voltage input and with double output shafts.

Low Voltage Gearmotors

Totally enclosed, permanent magnet DC gearmotors,

performance matched for continuous duty. Motors are

designed for battery power or can be used with a low

voltage controller with form factor up to 1.05.

Mechanical Specifications:

This worm-type right-angle gearing features hardened,

steel worm with bronze worm wheel for long life and

quiet operation. Precision machined aluminum housings

are used. Gearbox has all ball bearings. The housing is

sealed and lubrication is permanent with an oil bath. The

output shaft is field interchangeable from left hand style

to right hand style by reassembly.

Application Notes:

For optimum seal life, these

right-angle gearmotors

have a lubrication breather

positioned for horizontal

mounting. For other

mountings, the breather-

plug must be reoriented

by using a 90

1

/

8

” NPT taper

pipe elbow (see drawing). Elbow

not available from LEESON. Vent plug is available

(Part #M1900177_01). However, the motor portion of

the gearmotor should never be mounted below the

gearhead.

Overhung load capacities shown are at center of output

shaft.

Conduit box not supplied with motor.

See

page 171 for optional conduit box and optional base kit.

See page 205 for cross reference data between

LEESON and other gearmotors.

For additional information on LEESON gearmotors, see

Bulletin 1830.

10 SERIES - DC

13 SERIES - DC