115

Specifications are subject to change without notice

Gearmotors

IP55 WASHGUARD

™

GEARMOTORS

RIGHT ANGLE

General Specifications:

DC permanent

magnet gearmotors

rated for continuous

duty. Designed for

use with fullwave non-

filtered SCR controls

or battery supplied low

voltage for adjustable

speed applications

requiring constant torque

throughout the speed range.

Mechanical Specifications:

Gearbox output shafts are 303 stainless steel.

Frame, endshields, armature and interior

components protected by enamel and polyester

compounds for resistance to moisture, acids, alkalies

and oil.

Cast conduit box with threaded conduit holes and

Nitrile gaskets keep water out. The conduit box cover

is made from 304 stainless steel.

For any condensation that may accumulate inside

the motor a one-way stainless steel vapor vent

is provided. All hardware is stainless steel. Motor

painted with white epoxy for superior corrosion

resistance and protection.

Machined fits between the endbells and motor

frame are sealed with gaskets. Thru-bolt heads and

nuts sealed with fiber washers. O-rings under each

threaded brush cover.

This worm-type right-angle gearing features

hardened, steel worm with bronze worm wheel for

long life and quiet operation. Precision machined

aluminum housings are used. Gearbox has all ball

bearings. The housing is sealed and lubrication is

permanent with an oil bath.

Application Notes:

LEESON WASHGUARD™ motors are designed

for extended life in applications requiring regular

washdown or otherwise wet environments.

WASHGUARD™ motors retard the entrance of

water.

Extra protection for the motor’s interior prevents rust

and corrosion build-up and releases trapped moisture

to insure a longer life than possible with a standard

motor.

For optimum seal life, these right-angle gearmotors

have a lubrication breather positioned for horizontal

mounting. For other mountings, the breather plug

must be reoriented by using a 90 1/8 NPT taper pipe

elbow. See pages 111 or 120 for diagram.

Overhung load capacities shown are at center of the

output shaft.

The motor’s stall torque exceeds recommended full

load torques for the gearboxes. A current limiting

device should be used to prevent damage to the gear

sets.

, /Ê ÊUÊ- ,Ê, / Êä6

/ 6ÊUÊ£°äÊ- ,6 Ê

/",

Full Over-

DIMENSIONS

F.L.

Gearmotor

Arm Load hung

Output Torque Input

Catalog

Type &

Ratio Volts Amps Load

P

PB

X

XL

XH

RPM (Lb.In.) HP

Number

Frame

to 1

DC

DC (Lbs.)

Inches

42

80

1

⁄

8

M1125275

13F60-31 60 90 2.2 235 3.13 3.80 4.50 10.86 6.36

250 25

1

⁄

8

M1125276

13F10-31 10 90 2.2 235 3.13 3.80 4.50 10.86 6.36

62 135

1

⁄

4

M1125277

13F40-32 40 90 3.7 235 3.25 3.80 4.50 12.86 8.36

125 90

1

⁄

4

M1125278

13F20-32 20 90 3.7 235 3.25 3.80 4.50 12.86 8.36

250 50

1

⁄

4

M1125279

13F10-32 10 90 3.7 235 3.25 3.80 4.50 12.86 8.36

, /Ê ÊUÊ "7Ê6" / Ê£Ó6

/ 6ÊUÊ£°äÊ- ,6 Ê

/",

Full Over-

DIMENSIONS

F.L.

Gearmotor

Arm Load hung

Output Torque Input

Catalog

Type &

Ratio Volts Amps Load

P

PB

X

XL

XH

RPM (Lb.In.) HP

Number

Frame

to 1

DC

DC (Lbs.)

Inches

62 135

1

⁄

4

M1125280

13F40-32 40 12 28 235 3.25 4.43 4.50 12.36 7.86

125 90

1

⁄

4

M1125281

13F20-32 20 12 28 235 3.25 4.43 4.50 12.36 7.86

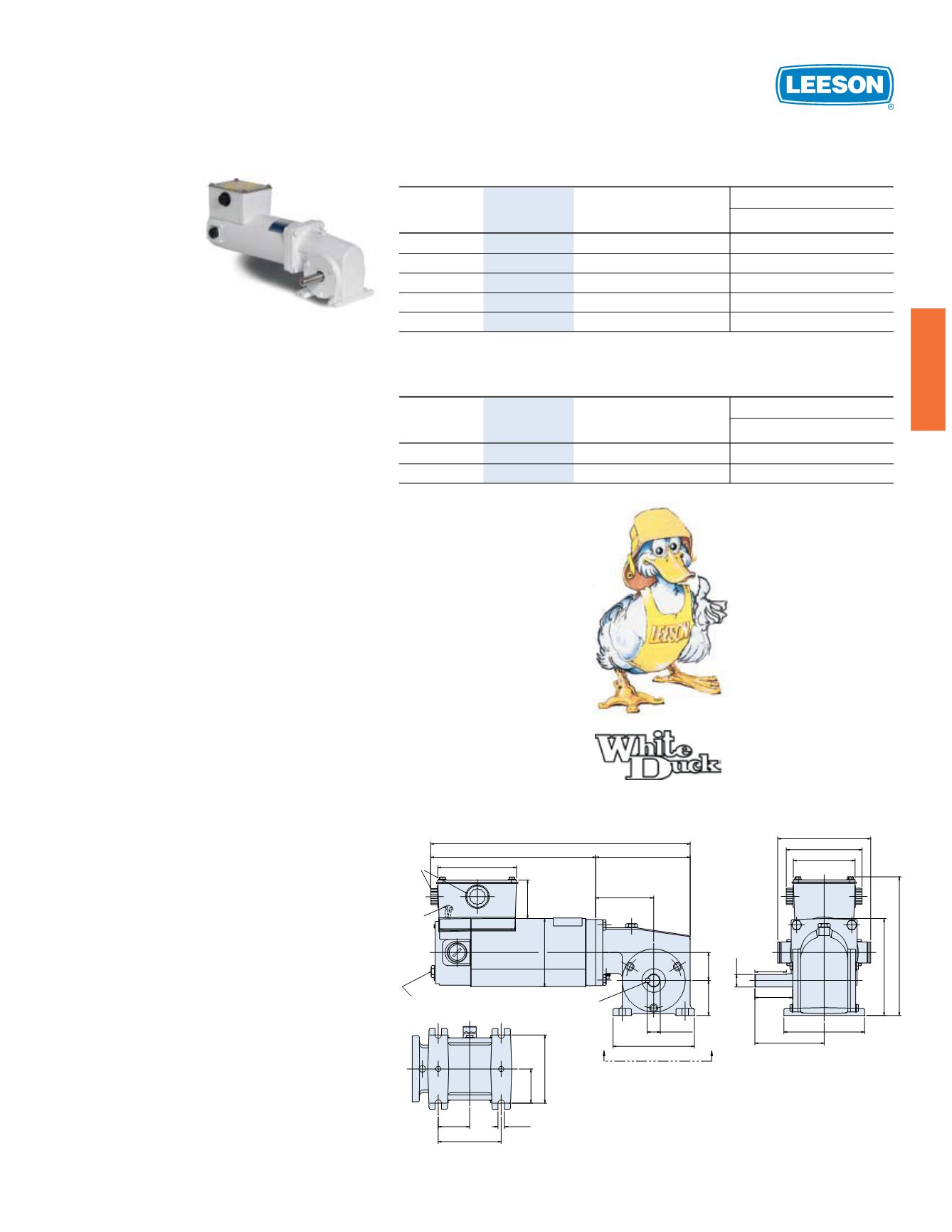

"XH"

3.75 REF

1/2 NPT

CONDUIT

PLUG

TOP

"P"

1.83 REF

"XL" REF

1.330

1.67

Ø625 .624

3.88 MAX

.187 SQ

X 1.13 LONG LEY

"Z"

"Z"

3.00

1.50

.31 TYP

3.25

1.625

VIEW "Z-Z"

MOTOR LEADS

6.00 LG MIN

2.94 REF

3.60 REF

"BD" REF

2.76

"X"

3.84 MAX

3.30

1.80

.593

FLAT

1.50

FLAT

4.62 MAX

"AF"

IMMERSION PROOF

BREATHER

13 SERIES - DC