Specifications are subject to change without notice

Gearmotors

114

IP55 WASHGUARD

™

GEARMOTORS

PARALLEL SHAFT

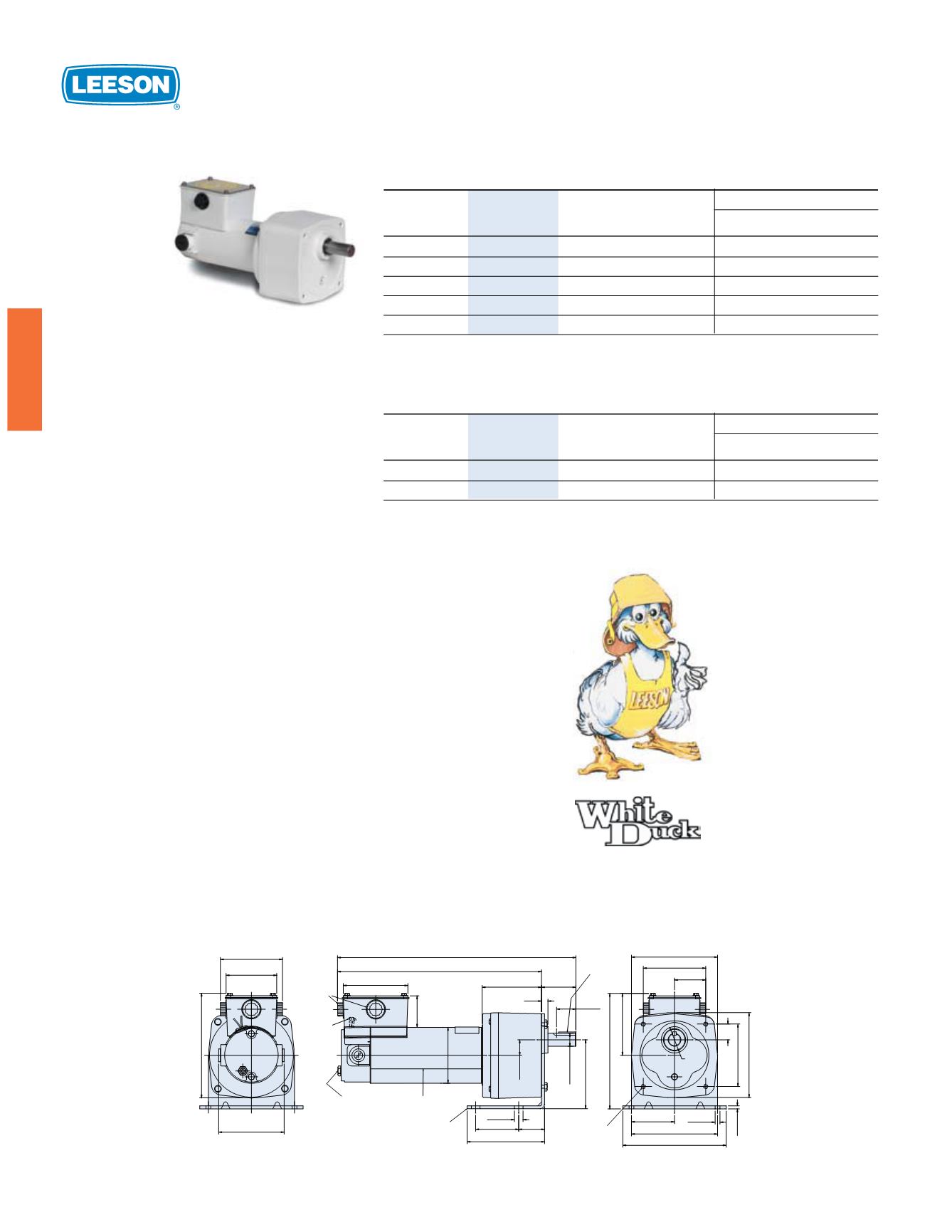

"XH"

"X"

"XL" REF

2.00

1/2 NPT

CONDUIT

PLUG

MOTOR

LEADS

6.0 LONG

MIN

Ø3.25

SCRIBE LINE

(FAR SIDE)

IMMERSION PROOF

BREATHER

3.75 REF

1.83 REF

.37

1.12

KEYWAY

Ø.750 .749

.90 REF

.50 TYP

2.500

1.50

4.50

"L" BRACKET

(OPTIONAL)

4.00

4.93

3.625

6.70 REF

6.00

5.000

2.50

.28 TYP

.18 REF

3.59 REF

5.00

3.625

1.812

.912

(4) 1/4-28 UNF-2B

.59 MIN. DEEP

(Ø5.125 BC REF)

Ø1.53

.19 SQ

x 1.00 LONG

KEY

TOP

"BD" REF

6.08

3.60 REF

2.94 REF

General Specifications:

DC permanent

magnet gearmotors

rated for continuous

duty. Designed for

use with fullwave

non-filtered SCR

controls or battery

supplied low voltage

for adjustable speed

applications requiring

constant torque throughout

the speed range.

Mechanical Specifications:

Gearbox output shafts are coated with Mirolon 3300

fortified Teflon for superior corrosion resistance.

Frame, endshields, armature and interior components

protected by enamel and polyester compounds for

resistance to moisture, acids, alkalies and oil.

Cast conduit box with threaded conduit holes and Nitrile

gaskets keep water out. The conduit box cover is made

from 304 stainless steel.

For any condensation that may accumulate inside the

motor a one-way stainless steel vapor vent is provided.

All hardware is stainless steel. Motor painted with white

epoxy for superior corrosion resistance and protection.

Machined fits between the endbells and motor frame are

sealed with gaskets. Thru-bolt heads and nuts sealed with

fiber washers. O-rings under each threaded brush cover.

Precision machined in-line steel gears, with a first stage

steel helical gear followed by spur-type gears. Lubrication

is permanent semi-fluid grease, reducing possibility of

leakage. Output shafts have needle bearings for high load

capacities.

Application Notes:

LEESON WASHGUARD motors are designed for

extended life in applications requiring regular washdown

or otherwise wet environments. WASHGUARD motors

retard the entrance of water.

Extra protection for the motor’s interior prevents rust and

corrosion build-up and releases trapped moisture to insure

a longer life than possible with a standard motor.

These gearmotors are designed for mounting at any

angle, but shaft up with motor below should be avoided

to prevent leakage of lubricant into the motor should the

shaft seal fail.

Overhung load capacities shown are at center of the

output shaft.

The motor’s stall torque exceeds recommended full load

torques for the gearboxes. A current limiting device should

be used to prevent damage to the gear sets.

PE350 SERIES PARALLEL SHAFT

/ 6ÊUÊ£°äÊ- ,6 Ê

/",ÊUÊ- ,Ê, / Êä6

Full Over-

DIMENSIONS

F.L.

Gearmotor

Arm Load hung

Output Torque Input

Catalog

Type &

Ratio Volts Amps Load

P

PB

X

XL

XH

RPM (Lb.In.) HP

Number

Frame

to 1

DC

DC (Lbs.)

Inches

14 341

1

⁄

8

M1125268

P353-31 180 90 1.5 465 3.13 3.80 3.45 11.84 9.84

42 280

1

⁄

4

M1125269

P353-32 58 90 2.6 327 3.25 3.80 3.45 13.84 11.84

83 155

1

⁄

4

M1125270

P353-32 29 90 2.6 267 3.25 3.80 3.45 13.84 11.84

250 45

1

⁄

4

M1125271

P352-32 10 90 2.6 201 3.25 3.80 3.45 13.84 11.84

500 25

1

⁄

4

M1125272

P352-32

5 90 2.6 194 3.25 3.80 3.45 13.84 11.84

PE350 SERIES PARALLEL SHAFT

/ 6ÊUÊ£°äÊ- ,6 Ê

/",ÊUÊ "7Ê6" / Ê£Ó6

Full Over-

DIMENSIONS

F.L.

Gearmotor

Arm Load hung

Output Torque Input

Catalog

Type &

Ratio Volts Amps Load

P

PB

X

XL

XH

RPM (Lb.In.) HP

Number

Frame

to 1

DC

DC (Lbs.)

Inches

14 341

1

⁄

8

M1125273

P353-31 180 12 12 465 3.13 4.43 3.45 11.58 9.58

42 325

1

⁄

4

M1125274

P353-32 58 12 20 327 3.25 4.43 3.45 13.84 11.84