176

Specifications are subject to change without notice

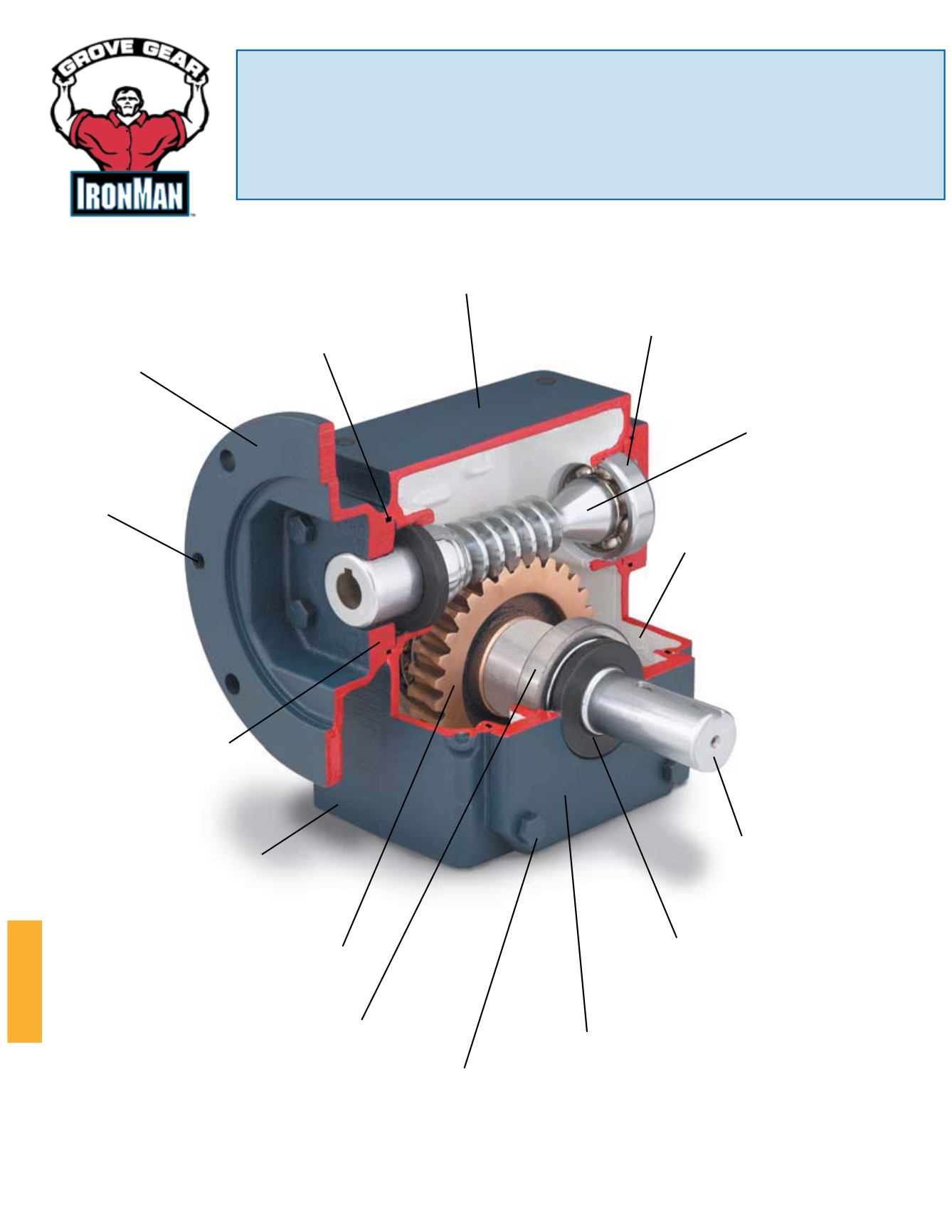

Gearing

Oversized positively-retained high speed

input shaft bearing

for higher shock load

capacity, shaft alignment and seal life. Ideal for

frequent starting and reversing applications.

Tapered roller bearings

on output shaft for

high overhung and thrust load capacities.

Robust output shaft

of

high strength steel alloy

for superior torque and

overhung load capacities.

Premium Grade 5

zinc-plated heat-

treated bolts

used throughout.

High capacity oil reservoir

reduces noise, aids heat

dissipation and lubricates

for life. Multiple venting

options for multi-position

mounting. Factory filled with

premium Mobil Glygoyle 460

polyalkalene glycol (PAG)

lubricant.

Viton

®

premium quality, double lip

seals**

throughout —on micro-finished

surfaces—mean extended life, resistance

to high temperature, abrasion and

chemicals.

Single-piece, alloy steel

input worm shaft.

High lead

angle worm is case-hardened,

ground and polished for

enhanced efficiency and noise

reduction.

** Sizes 813 through 852 only

IronMan

™

fine-grained, one-piece

cast housing

for rigidity and alignment.

Machined for precision alignment

of worm, worm gear, bearings and

mounting surfaces. Superior resistance

to environmental contaminants with high

heat dissipation and noise reduction.

Mounting dimensions are

interchangeable

with Baldor 900

series, Boston Gear, Browning

Raider, Falk, Morse Invader and other

“industry standard” reducers.

Cast iron IEC and NEMA C input

flange

with machined fits for

precision alignment of motor and

bearings.

Bronze alloy worm gear

is

premium quality bronze for

maximum strength, lubricity and

superior life.

O-rings on input and output

covers

eliminate gaskets,

sealants and leaks.

Precision mounting surfaces

and extra

threaded bolt holes on top and bottom for

flexibility and to accept a wide range of

stock mounting accessories.

800 Series Gear Reducers

Built For Industrial Use

Push-off holes

drilled

and tapped into flange

for quick motor removal

on quill input styles

(56 & 140TC frames).

Seal Guard**

on quill-input styles

protects input seal from damage

during motor installation.

Single output cover

design provides

precise centering

of gear for lower

noise levels and

higher overall gear

efficiencies.

Refer to Grove Gear / Electra-Gear Gearing Catalog 8050 for More Information