Specifications are subject to change without notice

Drives

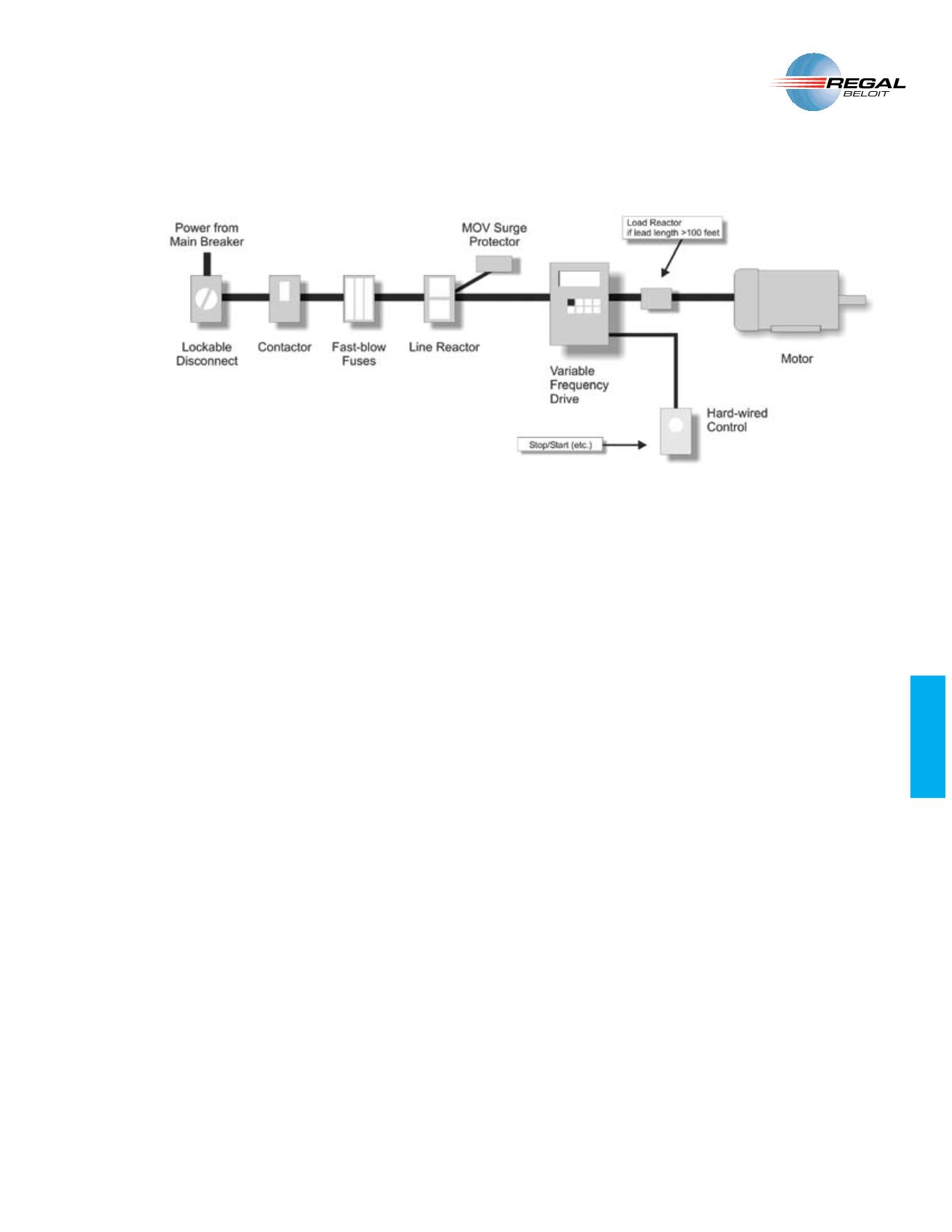

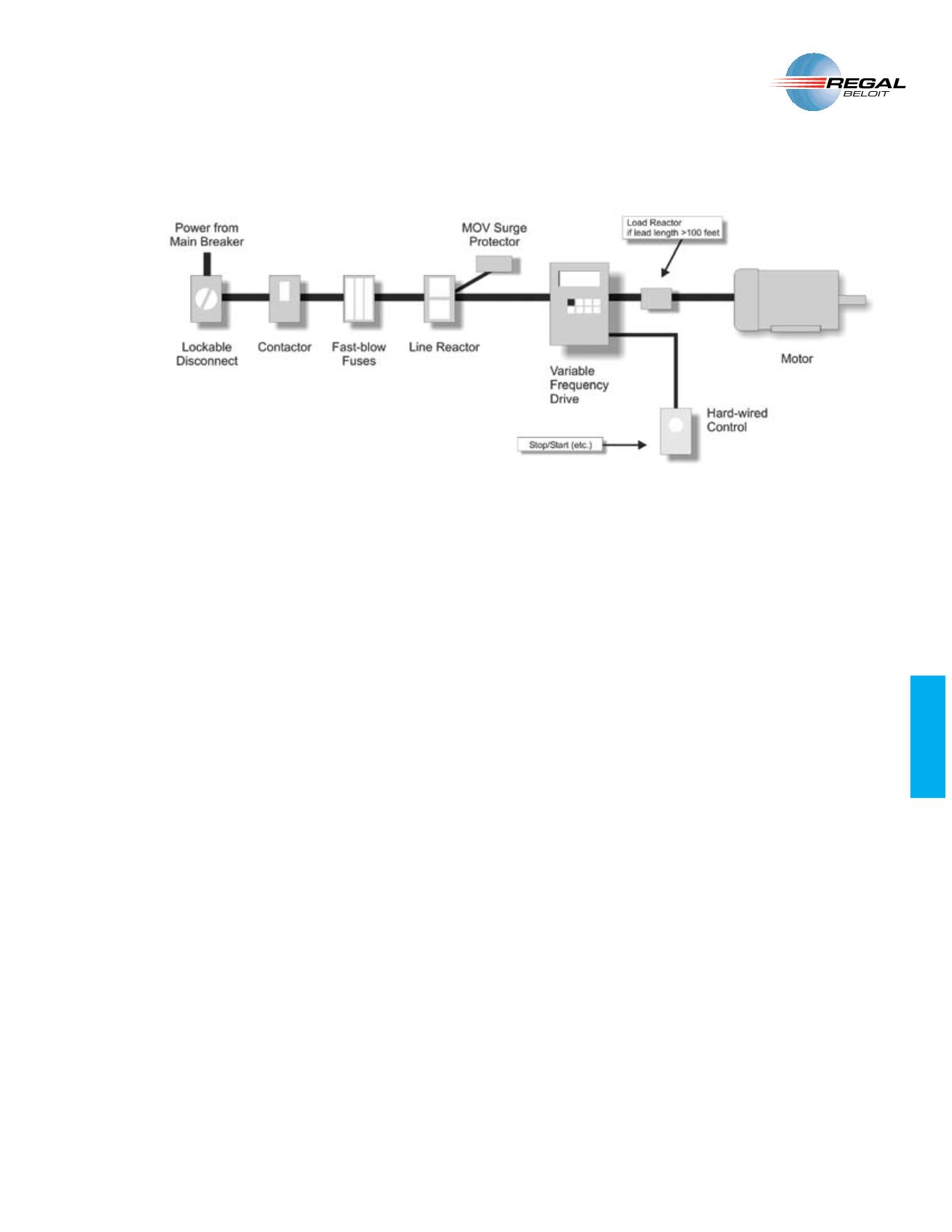

LOCKABLE DISCONNECT SWITCH (PG 169)

The lockable disconnect switch is designed to disconnect the main power

source, single or three phase.

CONTACTOR (PG 170)

The option of using a contactor ensures that the drive will not be damaged

due to any rapid fluctuations in power levels such as in a rainstorm or

thunderstorm where power may be cycling rapidly (check on the proper

electrical code for contactor and fuse configuration). In some types of

drives that have a standard DC Bus configuration the rapid cycling of line

side power may cause severe damage possibly requiring a new drive. This

is only a suggestion to be used in cases where heavy rainstorms occur and

the specific drive system is critical.

HIGH-SPEED FUSES (PG 158)

Most drives require high-speed fuses (also known as semiconductor rated

fuses). Because of their energy limiting characteristics, they are able to

protect semiconductor devices such as variable frequency drives from

excess energy let-through under fault current conditions.

The use of time delay fuses is not recommended as they are meant

for loads such as motors or heaters not electronic devices such as fax

machines, computers, and variable frequency drives.

LINE REACTOR (PG 154)

The line reactor is basically protecting the full wave rectifier on the front end

of the drive and the DC Bus (all those capacitors in the drive). It attenuates

most voltage anomalies and must be used were the voltage is 575 volts,

close to a power factor correction bank or where THD (Total Harmonic

Distortion) is high. The line reactor will attenuate most of these and is

always a good idea to use regardless since drives tend to be voltage

sensitive devices. N.B. The line reactor must be sized for the nominal load

that the drive is working at. If the line reactor is sized for the full load rating

and the drive only outputs half of its capability then the line reactor will not

provide adequate protection.

MOV SURGE PROTECTOR (PG 157)

The MOV Surge Protector will ensure that the full wave bridge rectifier on

the input side of the VFD will be protected from any dangerous voltage

transients and will reduce the effect of lightning. The use of an MOV is

recommended. This device is placed at the line reactor and is wired in

parallel with the incoming power line.

LOAD REACTOR/FILTER (PG 156)

)F THE MOTOR LEADS ARE WITHIN FEET IN LENGTH THEN NO ,OAD &ILTER IS

required as the motor windings will not experience any adverse effects

from Reflective Wave Phenomena. This applies to a Carrier Frequency

of 2.5KHZ; if higher, then leads must be shorter.

)F THE LEADS ARE OVER

FEET IN LENGTH THEN A ,OAD 2EACTOR &ILTER IS

required.

CONTROL WIRING (PG 157)

Control wiring to the drive from the station should be stranded, shielded and

18 to 24AWG in size. It should be wired directly to the input terminals of the

drive since dry contact signals are used for the discrete stop/start, forward/

reverse etc. The majority of control boards on most drives are totally iso-

lated from the drive itself and must not see any voltage via the control wire

to the drive’s control from either a radiated, conducted or

emitted source.

153

AC ADJUSTABLE SPEED DRIVES

GENERAL INFORMATION

VARIABLE FREQUENCY DRIVE SET-UP

Figure 1: Layout of a Nema 1 style drive. Notice that line side

power, control wires, and motor leads each have their own conduit.

It is extremely important not to cross the motor lead wires with any

other wire. If an enclosure is used, motor lead wires must be kept

away from all other control and power wiring.

Installation of the VFD should entail some basic components (Figure 1).

The following is a brief description of these components.

N.B. As with all

electrical equipment installation must be done by certified or licensed

personnel. Always check with provincial and federal standards and

codes for your area.