41

Refrigeration

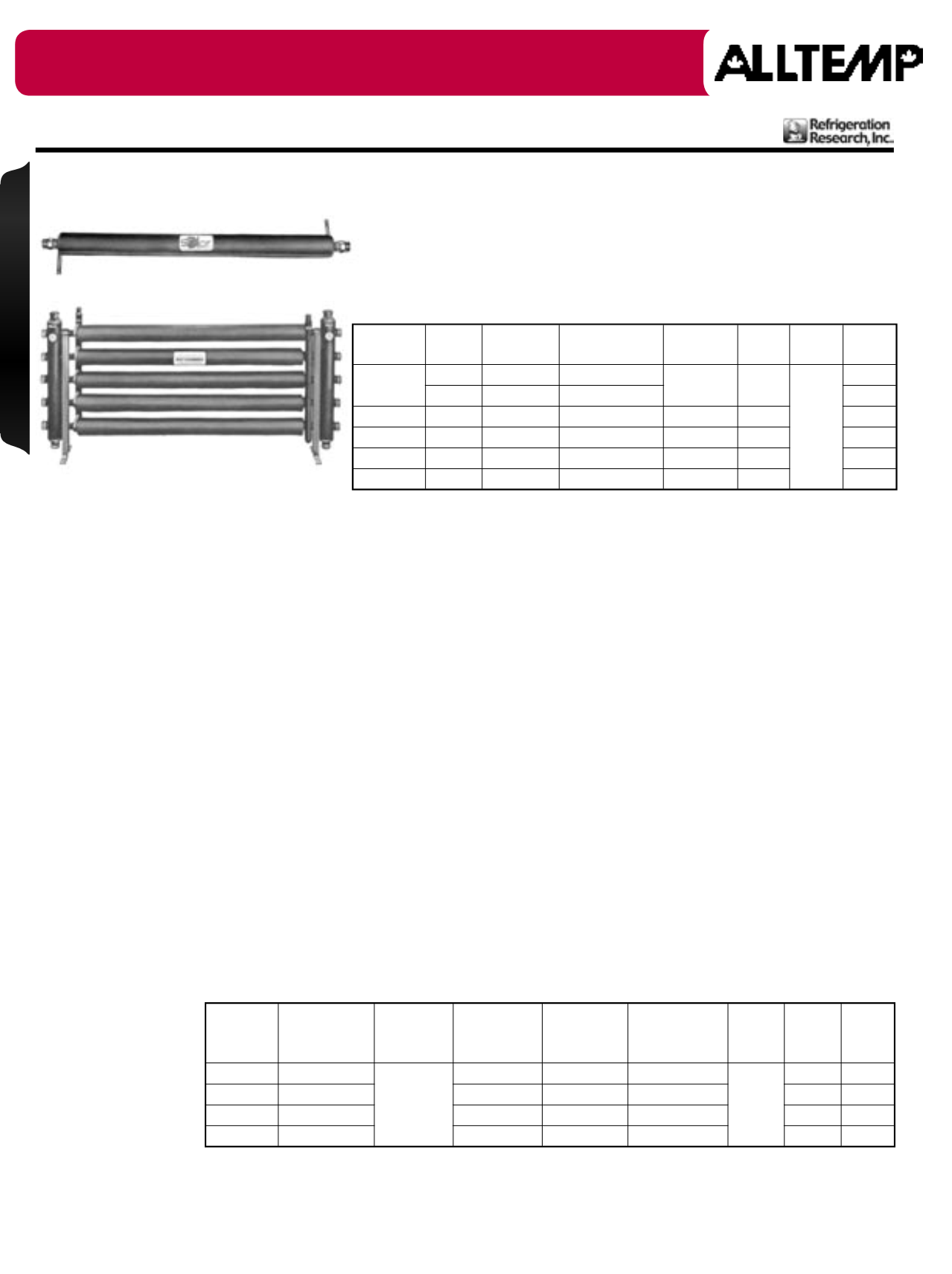

Double Wall Cleanable

Part # System

Max BTU/

Hr. Heated

Max Gal. to be

Heated 100°F

Horizontal

Tubes

Height Length

Weight

(lbs.)

49-5969

1 ton

2400

2.9

1

4.5"

37.0"

4.0

2 ton

4800

5.8

4.0

49-5975

3 ton

7200

8.7

2

10.5"

9.0

49-5976

5 ton 12000

14.4

3

14.5"

14.0

49-5977

71⁄2 ton 18000

21.5

4

18.5"

19.0

49-5978

10 ton 24000

29.0

5

22.5"

24.0

Desuperheating Heat Exchangers

Double Wall Cleanable

These practical double wall desuperheating heat exchangers are of

non-ferrous construction and provide a new standard of flexibility and

convenience. These units are used where local codes call for double

wall type heat exchangers. The entire inner surface is quickly cleaned

of water deposits with a wire brush by simply removing screw caps and

standard washers. There are no bolts and gaskets to remove.

Superheated Refrigerant Gas To Water

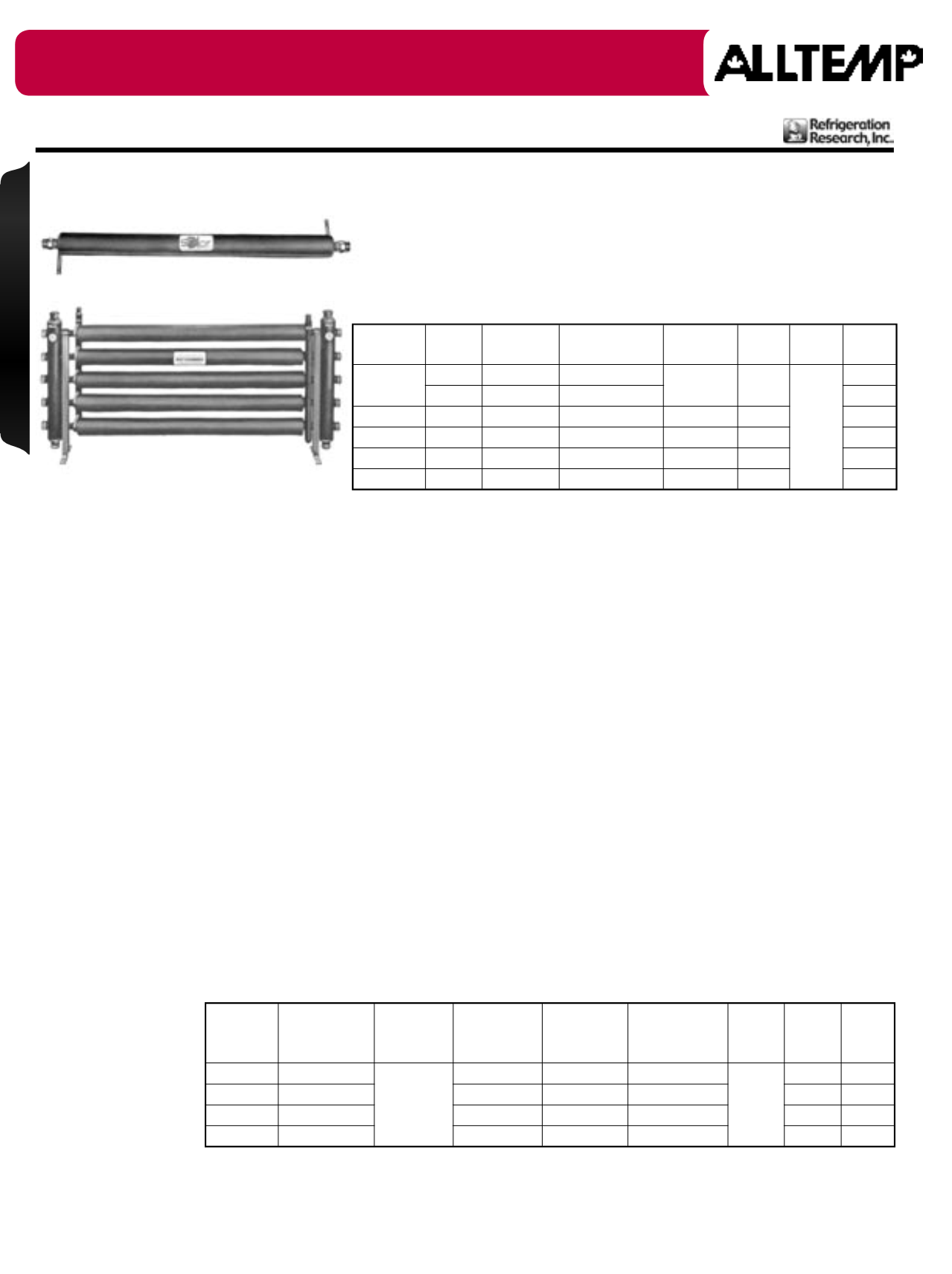

Part #

Refrigeration

Tons

Water Line

Opening

Refrig.

Gas Line

Opening

Max BTU/Hr.

Water

Heated

Max Gal. to be

Heated 50°F

to 50°F/ Hr.

Shell

Dia.

Length

Weight

(lbs.)

49-5836

3

5/8"

5/8"

7200

8.7

5.0"

9.0"

11.0

49-5837

5

7/8"

12000

14.4

13.0"

15.0

49-5838

71⁄2

1 1/8"

18000

21.5

18.0"

20.0

49-5839

10

1 3/8"

24000

29.0

23.0"

25.0

Desuperheating heat exchangers of smaller sizes are available on special request

Superheated Refrigerant Gas To Water

• Commercial refrigeration compressors can be used to provide an abundance of water at 150° (or even 180°)

while at the same time doing its intended refrigeration job and at a saving of perhaps 8 to 10% of the electrical

power it would normally require. This is accomplished by installing a heat exchanger designed for interchange

of heat between super-heated refrigerant gas and water. Such a system provides significant energy savings at a

comparatively low investment cost.

• This type of exchanger is installed in the discharge line between the commercial refrigeration compressor and the

condenser, whether it be water or air cooled style.

• In an ordinary commercial refrigeration system almost 30% of the condensers work is spent reducing the

superheated gas temperature to the condensing temperature. The balance of the condensers job is condensing

the gas to liquid and sub-cooling it.

• Therefore, if the above mentioned heat exchanger is designed to pick up only the heat of the superheat it is

assured that only high temperature water will be provided. At the same time if the existing water or air cooled

condenser does not have to handle the heat of superheat, it has additional capacity and the condensing

temperature and pressure will drop causing the compressor to require less power.

• Over sizing the heat exchanger would cause it to act somewhat as a water cooled condenser and the temperature

of the water to be heated would be much lower.

• With the addition of this type of heat exchanger it is also advisable to add an insulated hot water storage tank of

ample capacity.

• Usually these heat exchangers should be installed on commercial systems using automatic or thermostatic

expansion valves. Installation must always be made by a qualified refrigeration service engineer. If installation is

made on a capillary fed system it should be under the direction of a refrigeration engineer having knowledge of

capillaries.

Applications

• Commercial refrigeration

• Heat pumps

• Milk coolers

• Air conditioning, etc.

49-5969

1 &2 Ton

49-5978

10 Ton

Heat Exchangers